To optimize your turbocharger for maximum performance, start by selecting the right turbo type and guarantee it’s properly matched to your engine’s specifications. Fine-tune your engine’s air-fuel ratio and boost levels through ECU adjustments, and upgrade your cooling and oil systems to handle higher demands. Installing advanced materials and hybrid turbos can boost efficiency, while reducing lag with technologies like twin-scroll designs and external wastegates. Keep everything well-maintained to prevent faults—continue exploring to unleash even greater power.

Key Takeaways

- Properly match and upgrade your turbocharger considering engine size, boost needs, and exhaust flow for optimal performance.

- Regularly monitor boost pressure and response times to identify and address leaks or inefficiencies early.

- Use high-quality air filters, intercoolers, and cooling systems to maintain consistent intake temperatures and prevent heat soak.

- Fine-tune ECU settings for optimal air-fuel ratio, ignition timing, and variable camshaft timing adjustments.

- Maintain proper oil pressure, use advanced materials, and ensure clean lubrication to prolong turbo lifespan and sustain peak performance.

Understand Your Turbocharger Types and Matching Requirements

Understanding the different types of turbochargers and how to match them to your engine is essential for optimizing performance. Single-turbo setups are cost-effective and space-efficient, ideal for most applications. Twin-turbos provide better power delivery, especially in larger or performance cars. Twin-scroll turbos improve boost response by using separate exhaust paths, making them more efficient. Variable geometry turbos adjust turbine angles for better efficiency across speeds, perfect for versatile driving. Electric turbos combine traditional turbines with electric motors to reduce lag and boost low-speed performance. When matching a turbocharger, consider your engine size, boost pressure, exhaust system, intercooler needs, and cooling requirements. Proper matching ensures you get the best performance and longevity, preventing over-boosting or under-boosting that can harm your engine. Understanding turbocharger efficiency and how it impacts overall engine performance is crucial for making informed modifications. Additionally, considering turbo matching techniques can help maximize your setup’s effectiveness.

Fine-Tune Your Engine for Better Air-Fuel Efficiency

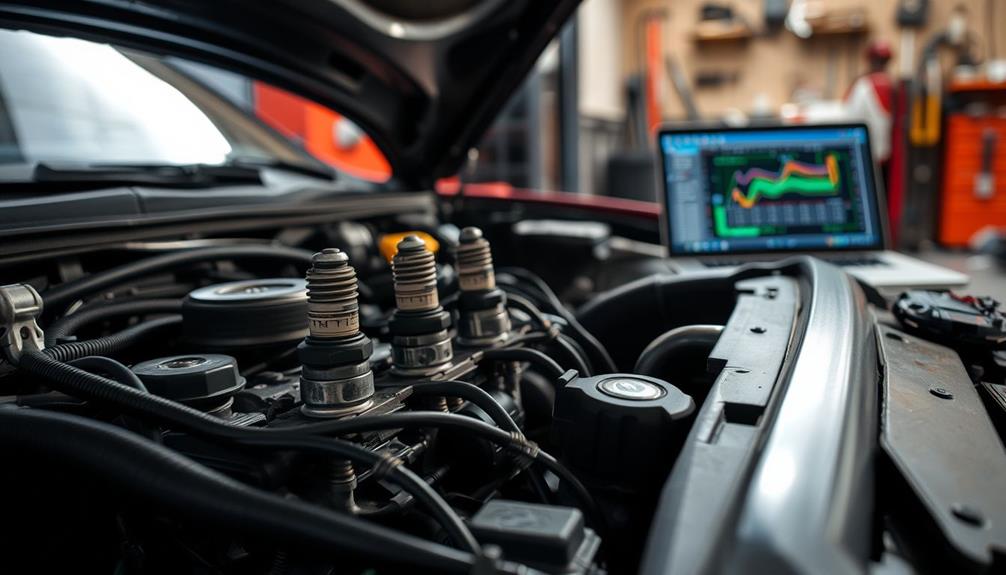

Optimizing your engine for better air-fuel efficiency can substantially boost performance and save fuel. Start by tuning your ECU, adjusting parameters like ignition timing and fuel injection to match your driving conditions. Focus on air-fuel ratio optimization to ensure a proper mixture, leading to more complete combustion. Utilize advanced systems like variable camshaft timing to reduce pumping losses during cruise. Incorporate high compression ratios and short burn durations to improve thermal efficiency. Regularly monitor engine performance with diagnostic tools and track fuel consumption to identify inefficiencies. Maintaining a clean air intake system ensures optimal airflow, which is crucial for maximizing turbocharger performance. Additionally, maintain proper tire pressure and adopt energy-efficient driving habits, such as steady speeds and avoiding unnecessary idling. Implementing real-time monitoring systems can help you make informed adjustments on the fly, further enhancing your engine’s efficiency. These adjustments help your engine run more efficiently, maximizing your turbocharger’s potential and overall vehicle performance.

Maintain Proper Oil Pressure and Use Quality Filtration

Maintaining proper oil pressure is essential for guaranteeing your turbocharger operates reliably and lasts longer. Aim for an oil pressure of 40-45 psi at maximum engine speed to prevent internal damage. Proper drainage setup is crucial to prevent oil backup and seal leaks, especially if the drain line is restricted or improperly routed. Use an oil restrictor with a 1.0-1.5 mm orifice or 0.040 inches for ball bearing turbos to control pressure effectively. Ensure your feed line is typically -3AN or -4AN with a matching ID for proper flow. At idle, around 30 psi may suffice with smaller lines like 1/4″ OD. Always verify the oil pressure after installing a restrictor to confirm correct operation. Additionally, use an oil filter that meets or exceeds OEM standards, with high-quality media for better particle capture. Regularly check and replace filters, and choose high-quality oil suited to your engine and turbo setup.

Upgrade Cooling Systems and Intercoolers for Enhanced Performance

Upgrading your cooling systems and intercoolers plays a vital role in boosting your turbocharged engine’s performance. Air-to-air intercoolers cool compressed air with ambient air, improving air density and combustion efficiency. Intercoolers help reduce intake air temperature, which is crucial for maintaining optimal combustion conditions. Upgrading these components can also help mitigate heat soak, which diminishes performance during extended driving or high loads. Air-to-water intercoolers use liquid coolant for faster heat transfer, making them ideal for space constraints and quick thermal response. Both types lower intake air temperature, increasing oxygen content and reducing the risk of detonation. Upgraded cooling systems, including enhanced intercoolers and coolant capacity, help manage higher boost pressures and prevent overheating. Water-cooled turbochargers circulate water through the housing, reducing heat soak and extending turbo life. Proper installation, regular maintenance, and quality coolant guarantee consistent cooling performance, enabling your engine to produce maximum power reliably under aggressive tuning conditions.

Reduce Turbo Lag With Advanced Technologies and Driving Techniques

Reducing turbo lag is vital for getting the most responsive and efficient performance from your turbocharged engine. Advanced technologies like twin scroll turbochargers and electric assist systems help minimize lag by optimizing exhaust flow and providing instant boost. Turbo lag, a delay in response during acceleration, can be significantly reduced with these innovations. Incorporating Kia Tuning techniques such as ECU remapping and exhaust upgrades can further enhance turbo performance. Driving techniques also play a key role; maintaining engine RPM within ideal ranges ensures your turbo stays spooled. Additionally, smooth throttle inputs prevent unnecessary pressure drops, keeping boost steady. To deepen your understanding:

- Use electric-assisted turbochargers for immediate boost response.

- Shift gears strategically to keep RPM in the turbo’s sweet spot.

- Apply gradual throttle inputs to avoid sudden pressure drops and lag.

Consider Aftermarket Upgrades for Turbo, Intercooler, and Intake System

Optimizing your turbocharged engine doesn’t end with driving techniques; investing in aftermarket upgrades can markedly boost performance. Upgrading your turbocharger increases airflow and reduces exhaust backpressure, boosting horsepower and drivability. Larger, efficient turbos lower exhaust gas temperatures during heavy acceleration, protecting your engine. Choosing the right size turbo—supporting up to 150HP over stock—maintains boost response and reliability. An upgraded intercooler cools intake air more effectively, supporting higher boost levels and reducing knock risk. A high-flow intake system reduces airflow restrictions, increasing efficiency and power. To help visualize, here’s a quick comparison: performance gains

| Upgrade Type | Benefits |

|---|---|

| Turbocharger | Increased airflow, power gains, reduced EGTs |

| Intercooler | Cooler intake air, supports higher boost, engine safety |

| Intake System | Better airflow, more consistent temperatures |

| Fuel/Engine Hardware | Meets increased fuel and pressure demands, maintains reliability |

Leverage Technological Innovations Like Hybrid Turbo Systems and Advanced Materials

Technological innovations are revolutionizing turbocharger performance, with hybrid systems and advanced materials leading the charge. Hybrid turbo systems combine parts from different models, boosting power and efficiency while reducing lag. They’re often cost-effective and easy to install, following a “bolt-on” approach, and many meet legal standards, making them practical upgrades. Hybrid systems are designed to be adaptable to various engine types, making them versatile choices for performance upgrades. Advanced materials enhance durability and performance through precision manufacturing and new composites that withstand high loads. The use of advanced manufacturing techniques allows for tighter tolerances and better material integration, further improving reliability. Innovations like 360° thrust bearings and bespoke parts allow for tailored performance. To maximize benefits, consider these key points:

- Opt for hybrid systems to improve power with minimal hassle.

- Use advanced materials for longer-lasting, high-performing components.

- Incorporate electric hybrid tech for smoother, quicker boost response. Additionally, integrating cutting-edge technology can further elevate your turbo’s efficiency and lifespan.

Monitor Performance Metrics and Conduct Regular Maintenance Checks

Monitoring your turbocharger’s performance and performing regular maintenance are essential steps to guarantee it operates at peak efficiency and longevity. Keep an eye on boost pressure with aftermarket gauges, ensuring PSI stays within the 6-10 range for stock setups, and compare readings to compressor maps to stay within the ideal efficiency zone. Watch for pressure drops signaling leaks, and monitor response times to catch carbon buildup or bearing friction early. Proper tuning and calibration of boost levels can prevent compressor surge and extend turbo life. Regularly log data across different RPMs and loads to spot wastegate or actuator issues. Additionally, schedule maintenance like replacing air filters every 15-20k miles, changing oil every 5k miles, and cleaning sensors quarterly. Inspect intercoolers biannually and keep coolant levels topped to prevent overheating. Consistent monitoring and upkeep keep your turbo running smoothly and efficiently.

Detect and Address Turbocharger Faults Early to Prevent Damage

Detecting turbocharger faults early can save you from costly repairs and prevent engine damage. You should focus on real-time pressure and performance monitoring, which helps identify issues like leaks or blockages before they worsen.

Here are key ways to stay ahead:

- Monitor pressure deviations: Changes in air pressure or engine data can signal early faults, enabling quick intervention.

- Use vibration analysis: Detect shifts in vibration frequencies indicating shaft imbalance, bearing wear, or misalignment.

- Leverage machine learning: Automated models analyze complex data, recognizing subtle faults before physical symptoms appear.

Develop a Strategic Upgrade Plan Based on Performance Goals

Before upgrading your turbocharger, it’s important to clearly define your performance goals. Know whether you need more horsepower for racing, torque for towing, or efficiency for daily driving. Consider your typical driving conditions—terrain, load, and usage frequency—to guide your choices. Review your engine specs, like displacement, compression ratio, and RPM, to guarantee compatibility. Establish a budget that balances performance gains with necessary modifications. Use this plan to prioritize upgrades and avoid overspending. Here’s a quick overview:

| Goal | Key Consideration | Result |

|---|---|---|

| Max horsepower | Turbo size, ECU tuning | Increased power |

| Towing capacity | Intercooler, exhaust modifications | Better load handling |

| Fuel efficiency | Turbo type, fuel system upgrades | Lower fuel consumption |

| Response | Turbine wheel, boost control | Quicker throttle response |

| Reliability | Material quality, maintenance | Longer turbo lifespan |

Frequently Asked Questions

How Often Should I Service My Turbocharger for Optimal Performance?

You should service your turbocharger at least annually or during major maintenance, inspecting components like oil lines, seals, and bearings.

Follow the manufacturer’s recommended intervals for oil changes, usually every 5,000 to 7,500 miles, and replace air filters every 12,000 to 15,000 miles.

Regularly check for leaks, clean intercoolers, and monitor boost pressure to keep your turbocharger running smoothly and maximize performance.

Can Tuning Alone Eliminate Turbo Lag Completely?

Imagine a race car with a finely tuned electronic boost controller. Tuning alone can markedly reduce turbo lag by optimizing boost pressure and wastegate settings, but it won’t eliminate lag entirely.

For example, adding electrically assisted turbos or twin-scroll designs can provide near-instant response. Ultimately, combining tuning with technological upgrades offers the best chance to minimize turbo lag, but some residual delay remains inevitable due to physics.

What Are Signs of a Failing Turbocharger?

When your turbocharger starts failing, you’ll notice reduced power and slower acceleration. Throttle response becomes poor, and you might see a lack of boost, making your car less agile.

Excessive exhaust smoke, oil leaks, and increased oil consumption are clear signs. Listen for whining, squealing, or rattling noises, and watch for vibrations or loud startup sounds.

An illuminated check engine light or diagnostic trouble codes also point to turbo problems.

Are Aftermarket Turbo Upgrades Worth the Investment?

Think of upgrading your turbo as giving your engine a shot of adrenaline. If you want more power, better airflow, and enhanced durability, aftermarket turbos are worth it.

They can boost performance at higher RPMs, reduce lag, and improve efficiency. However, weigh the costs, compatibility, and maintenance needs.

When professionally installed and properly tuned, these upgrades can transform your ride into a performance beast worth every penny.

How Does Ambient Temperature Affect Turbo Efficiency?

Ambient temperature considerably impacts your turbo’s efficiency. When temperatures rise, the air becomes less dense, meaning less oxygen enters the engine, and the turbo has to work harder, reducing its performance.

Cooler temperatures improve air density, allowing your turbo to operate more effectively and deliver better boost. Warmer air also strains the intercooler, making it less efficient.

To maximize performance, keep intake air cool and consider modifications that help manage heat.

Conclusion

By following these tips, you can maximize your turbocharger’s performance without risking damage or costly repairs. Some might worry that upgrades are complicated or expensive, but with proper maintenance and strategic enhancements, you’ll enjoy improved power and efficiency. Think of it as tuning your car for peak performance—investing a little time and effort now guarantees smoother rides and lasting results. So don’t hesitate—take control and realize your turbo’s full potential today.