S58 crank hub failures are often caused by manufacturing defects, improper installation, or lack of maintenance, leading to early breakdowns and costly repairs. Poor quality control can hide flaws until the hub fails unexpectedly. To prevent this, you should regularly inspect for wear, guarantee correct torque on bolts, and follow proper maintenance routines. Addressing issues early is vital, and if you’re concerned about persistent problems, more details await those who keep exploring.

Key Takeaways

- Many S58 crank hub failures result from manufacturing defects, not user error, often causing cracks, loosening, or total breakdowns.

- Proper maintenance, including regular inspections and correct bolt torque, significantly extends the lifespan of the crank hub.

- Early failures can stem from flawed manufacturing or improper installation, highlighting the importance of professional diagnosis.

- Manufacturers may offer warranties for defective hubs; early issues often require repair, replacement, or component upgrades.

- Preventative measures, such as quality assembly and adherence to maintenance routines, reduce the risk of premature S58 crank hub failures.

If you’ve experienced issues with your S58 crank hub, you’re not alone. Many riders have encountered problems that seem to stem from manufacturing defects or the way the hub is maintained over time. Understanding the root causes can help you decide whether to seek a warranty replacement, attempt repairs yourself, or consider upgrading to a more reliable component.

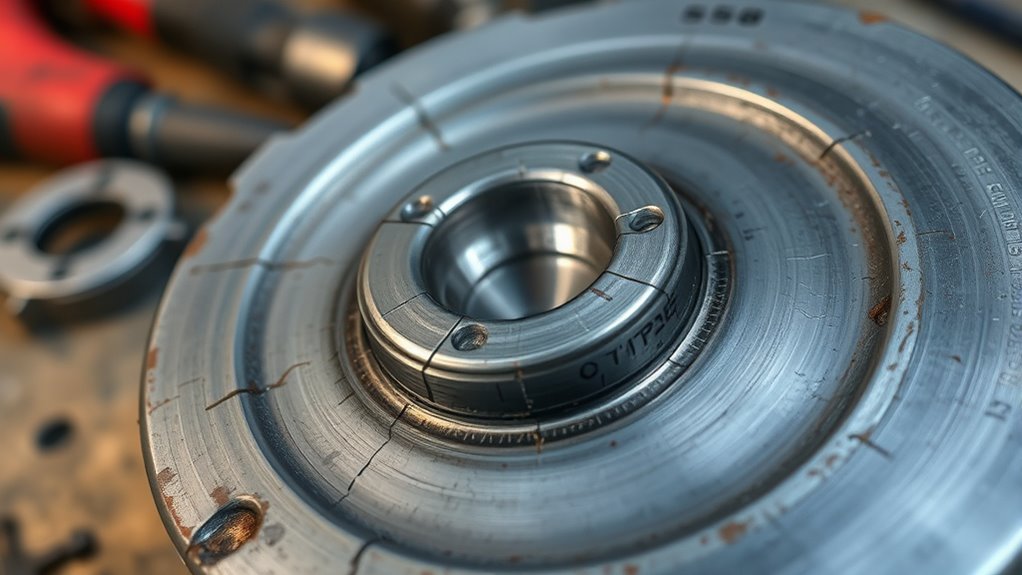

Manufacturing defects are a common culprit behind early crank hub failures. Sometimes, during the production process, imperfections occur—such as improper assembly, subpar materials, or insufficient quality control—that compromise the hub’s durability. These flaws might not be immediately obvious but can lead to cracks, loosening, or complete failure after just a few rides. If your crank hub starts showing signs of wear or damage shortly after installation, it’s worth inspecting for potential manufacturing issues. Contacting the manufacturer for a warranty claim is often the best course of action, especially if the product is still within its coverage period. Recognizing that these defects are not your fault can save you from unnecessary frustration and expense.

Manufacturing defects can cause early crank hub failures, leading to cracks, loosening, or complete breakdown.

However, even the best-made hubs can fail prematurely if not properly maintained. User maintenance plays a vital role in extending the lifespan of your crank hub. Regularly checking for signs of wear, such as unusual noises, play in the crankset, or visible damage, helps catch problems early. Applying correct lubrication and ensuring that bolts are torqued to the manufacturer’s specifications prevents undue stress on the hub components. Over-tightening or neglecting maintenance can accelerate fatigue and contribute to failure, regardless of the hub’s initial quality. It’s essential to follow the recommended maintenance routine, including cleaning and inspecting your crankset periodically, to avoid avoidable issues. Additionally, understanding the importance of proper installation can prevent many common problems related to hub failure.

If you do encounter problems, diagnosing whether they come from manufacturing defects or user maintenance is key. Early failures often coincide with improper setup or neglect, but they can also be a sign of a flawed product. When in doubt, consulting with a professional mechanic can help determine whether your crank hub needs repairs, replacement, or if you should consider upgrading to a more robust model. Remember, addressing these issues promptly minimizes the risk of more severe damage and keeps your rides smooth and safe.

Ultimately, understanding the impact of manufacturing defects and proper user maintenance empowers you to make informed decisions. Whether it’s seeking warranty support or adjusting your maintenance habits, taking proactive steps ensures you enjoy a reliable, long-lasting crank hub experience.

Frequently Asked Questions

Can S58 Crank Hub Failures Be Prevented With Regular Maintenance?

Regular maintenance can markedly reduce the risk of S58 crank hub failures. By performing preventive maintenance, you catch early signs of wear or damage before they worsen. Keep an eye on the crank hub’s condition, and schedule routine inspections. Early detection of issues allows you to address them promptly, preventing failure. Staying proactive with maintenance ensures your engine runs smoothly and extends the lifespan of your crank hub.

Are Aftermarket Solutions More Reliable Than OEM Parts?

Think of aftermarket solutions as bold new explorers venturing into uncharted territory, promising greater durability than OEM parts. When comparing, you find aftermarket parts often boast enhanced durability, but OEMs stick to proven reliability. You’re the captain of your ride, so weigh the risks and rewards. While aftermarket options might offer added strength, trust in OEM parts guarantees your engine’s heart stays steady and true, avoiding unforeseen failures.

How Long Does a Typical S58 Crank Hub Repair Take?

A typical S58 crank hub repair usually takes around one to three days, depending on diagnostic procedures and parts availability. You’ll want to have a professional assess the issue thoroughly to determine the exact cause. The repair timeline can vary, but prompt diagnostics help minimize downtime. Expect a skilled mechanic to quickly identify the problem and complete the repair efficiently, restoring your vehicle’s performance with minimal delay.

What Are the Signs of Imminent Crank Hub Failure?

You might notice symptom identification signs like unusual noises, increased vibrations, or inconsistent shifting, which signal imminent crank hub failure. Pay attention to these warning signs early on. Regular maintenance tips include checking for loose bolts, inspecting for wear or damage, and listening for any abnormal sounds during rides. Addressing these issues promptly can help prevent more severe damage, ensuring your bike stays safe and performs ideally.

Is It Cost-Effective to Replace the Entire Crank Hub Assembly?

Think of replacing the entire crank hub assembly like swapping out a worn-out gear; it can be costly but might save you trouble down the road. You should weigh the cost comparison with part longevity—if the new assembly lasts longer, it’s often worth it. While replacing the whole unit may seem expensive upfront, it can be more cost-effective over time, especially if repairs keep recurring.

Conclusion

Now that you know the real deal behind S58 crank hub failures, you’re better equipped to tackle the issue head-on. Don’t let a faulty hub turn your ride into a junkyard – with the right fixes, you’ll keep your engine roaring like a beast. Remember, ignoring these problems is like playing with fire; it’ll only lead to bigger disasters. Stay vigilant, follow expert advice, and keep that crank spinning smoothly for miles to come!