If you’re looking for the best torque angle gauges to get perfect tightening, I recommend checking out options like the SF0136, Lisle 28100, and OTC 4554, which are known for accuracy and durability. These tools help make sure fasteners are tightened exactly to the right angle, preventing over or under-tightening. To find the right fit for your needs and see top models, keep an eye on key features like measurement range, construction quality, and compatibility. If you continue, you’ll discover more about choosing the perfect one.

Key Takeaways

- Choose gauges made from durable materials like chrome-vanadium steel for long-lasting accuracy.

- Opt for models with clear 2° graduations and quick reference intervals for precise, easy readings.

- Ensure compatibility with standard 1/2-inch drive tools for versatile use in automotive applications.

- Look for features like adjustable arms, flexible clip mounts, and zero-reset functions for ease of operation.

- Prioritize gauges with reliable calibration, sturdy construction, and positive user reviews for consistent performance.

1/2 Inch Torque Wrench Angle Gauge Tool

If you’re a professional auto mechanic or someone who demands precise torque and angle measurements, the Inch Torque Wrench Angle Gauge Tool is an excellent choice. I find its 360° adjustable feature incredibly useful, allowing me to measure torque and angle quickly and accurately. Made of durable chrome-vanadium steel, it withstands tough working conditions and lasts long. The transparent housing makes it easy to read, while the knurled knob and flexible arm provide customizable setups. With no batteries needed, it’s a reliable mechanical tool that helps me meet strict specifications, especially for bolts and nuts like bearing covers. It’s a dependable addition to my toolkit.

Best For: professional auto mechanics and DIY enthusiasts who require precise torque and angle measurements for automotive and heavy-duty applications.

Pros:

- Durable chrome-vanadium steel construction ensures long-lasting performance in tough working conditions

- 360° adjustable feature with clear dial allows for quick, accurate measurement of torque and angle

- Mechanical operation requires no batteries, providing reliable and maintenance-free use

Cons:

- Finish is unpolished, which may be less aesthetically appealing or prone to minor scratches over time

- Compact size and lightweight design might limit leverage for certain tasks

- Suitable for torque values up to 1 inch-pound, potentially limiting use for higher torque applications

1/2 Inch Torque Wrench Angle Gauge Tool SF0136

The Inch Torque Wrench Angle Gauge Tool SF0136 is perfect for DIY enthusiasts and mechanics who need precise angle measurements in tight spaces. It features a 360-degree scale marked at 2-degree increments, making it easy to measure rotation accurately. The tool has a male and female 1/2-inch square drive, with an adjustable holding rod that offers two length options for flexibility. Its mechanical design, combined with a polished finish, ensures durability and ease of use. Ideal for complex tasks like tightening cylinder head bolts, this gauge helps achieve exact angles, improving precision and reliability in torque applications.

Best For: DIY enthusiasts and mechanics who require precise torque angle measurements in tight or hard-to-reach spaces.

Pros:

- Features a clear 360-degree scale marked at 2-degree increments for accurate measurement

- Adjustable holding rod with two length options adds flexibility to various applications

- Mechanical design with a polished finish ensures durability and ease of use

Cons:

- Some users have reported that the construction may not be overly sturdy and requires careful handling

- The holding bar may need adjustment or can be difficult to lock in place initially

- There is a risk of gauge cracking if mishandled or used improperly, which can impair functionality

Lisle 28100 Torque Angle Meter, 1/2 Inch Drive, Universal Fit, Skin-Pack

For professionals and DIY enthusiasts who need precise torque-to-yield fastener tightening, the Lisle 28100 Torque Angle Meter with a 1/2 inch drive offers a universal fit that simplifies the process. Its design makes it suitable for tightening head bolts and other bolts requiring torque angle specifications. Compatible with 1/2 inch drive tools, it’s versatile and easy to use across various applications. Packaged in a convenient skin-pack, it’s portable and ready for quick deployment. Whether working on engines or other machinery, this gauge guarantees accurate torque-to-yield tightening, helping prevent over-tightening or damage, and promoting consistent, reliable results every time.

Best For: DIY enthusiasts and professional mechanics needing precise torque-to-yield fastener tightening in various automotive and machinery applications.

Pros:

- Universal fit compatible with 1/2 inch drive tools for versatile use

- Designed specifically for torque angle tightening, ensuring accuracy

- Compact skin-pack packaging makes it portable and easy to store

Cons:

- May require experience to read and interpret torque angles correctly

- Not suitable for torque applications outside of torque-to-yield fasteners

- Limited to 1/2 inch drive tools, restricting use with other drive sizes

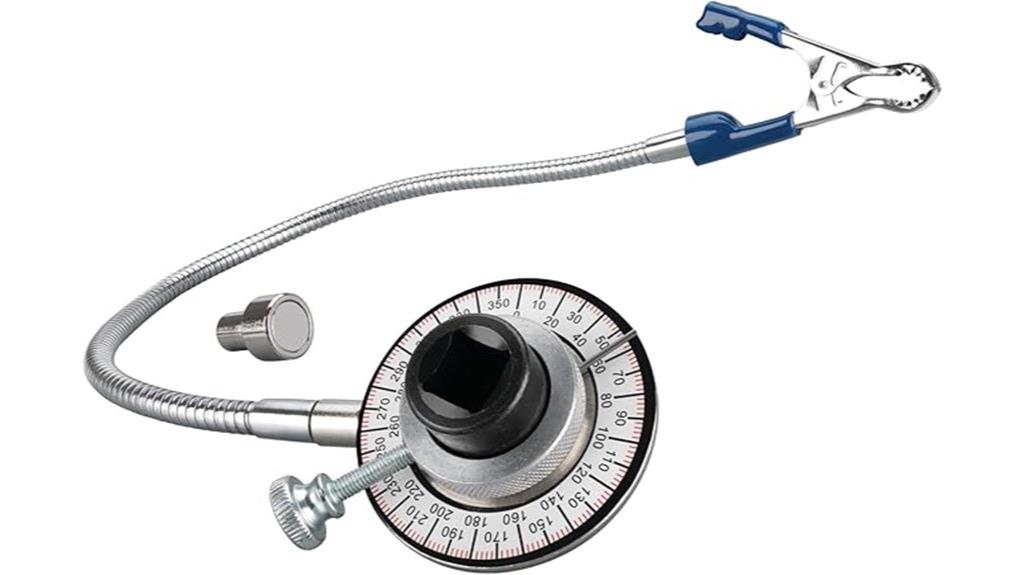

Torque Angle Meter for 1/2 Drive Wrench

A torque angle meter designed for 1/2 drive wrenches is ideal for professionals and enthusiasts who need precise control when tightening bolts by angle rotation. I appreciate its sturdy CR-V steel construction with chrome plating, ensuring durability and corrosion resistance. The 14-inch flexible clip arm makes it easy to reach tight, awkward spots, while the 0°-360° range offers versatile measurement. With a torque capacity of up to 280 Nm and 2-degree accuracy, it guarantees accurate tightening. Zeroing the device is simple, allowing quick resets for multiple tasks. Overall, this mechanical tool provides reliable, precise torque control without batteries, making it a must-have for critical fastener work.

Best For: professionals and enthusiasts who require precise torque control when tightening bolts by angle rotation, especially in hard-to-reach areas.

Pros:

- Durable CR-V steel construction with chrome plating for corrosion resistance

- Flexible 14-inch clip arm for easy access in tight or awkward spaces

- Mechanical design without batteries, ensuring reliable, maintenance-free operation

Cons:

- Limited to a maximum torque of 280 Nm, which may not suit extremely high-torque applications

- Requires manual zeroing for each use, potentially adding time during projects

- No digital readout; relies on mechanical gauge which may be less convenient for quick readings

1/2 Inch Torque Wrench with Angle Gauge

If you’re a professional mechanic or work in heavy-duty industrial settings, an inch torque wrench with an angle gauge is essential for achieving precise fastener tightening. This tool combines a 1/2-inch drive torque wrench with a 360° adjustable angle gauge, allowing for accurate torque application and angle measurement. Its clear dial, marked in 2° and 10° increments, enables quick, reliable readings. The adjustable arm provides flexibility for different tasks, while the knurled knob ensures precise calibration. Built for demanding environments, this wrench guarantees consistent, professional results, helping you meet manufacturer specifications and avoid over-tightening or under-tightening.

Best For: professional auto mechanics and industrial technicians requiring precise torque and angle measurements for heavy-duty fastening tasks.

Pros:

- Accurate 360° adjustable angle gauge with clear, easy-to-read dial in 2° and 10° increments

- Durable construction suitable for demanding professional environments

- Adjustable arm and knurled knob for quick calibration and versatile use

Cons:

- May be heavier and bulkier than basic torque wrenches, affecting maneuverability

- Requires proper calibration for consistent accuracy over time

- Higher cost compared to standard torque wrenches without angle measurement features

OTC 4554 1/2 Drive Torque Angle Gauge

The OTC 4554 1/2 Drive Torque Angle Gauge stands out as an essential tool for technicians working on late-model engines that require torque-to-yield fasteners. It features a 360-degree scale marked in 2-degree increments, making it easy to measure precise rotation angles after pre-torque. The gauge is simple to calibrate for multiple uses by turning the housing, and it fits standard 1/2-inch drives, ensuring compatibility with common tools. This gauge helps ensure accurate, consistent tightening of fasteners, reducing the risk of over-tightening or under-tightening. It’s a reliable choice for achieving perfect torque-to-yield results every time.

Best For: Automotive technicians and mechanics working on late-model engines requiring precise torque-to-yield fastener installation.

Pros:

- Provides accurate 360-degree measurement in 2-degree increments for precise torque application

- Easy to zero and calibrate for multiple uses, increasing efficiency

- Compatible with standard 1/2-inch drive tools, ensuring broad usability

Cons:

- May require additional training to use effectively on complex assemblies

- Limited to 1/2 drive applications; not suitable for other drive sizes

- The scale’s resolution might be insufficient for extremely fine torque adjustments in some cases

TAODAN Adjustable Drive Torque Gauge Wrench Set

For professional machinists and automotive technicians who demand precise torque and angle measurements, the TAODAN Adjustable Drive Torque Gauge Wrench Set offers an essential tool. It measures torque angles up to 360 degrees in 2-degree increments, with 10-degree intervals for quick reference. The adjustable arm in two lengths provides versatility for various applications. Made from durable chrome vanadium steel, it guarantees long-lasting performance. The set includes a reliable torque angle gauge and a 1/2-inch drive wrench, all compact and easy to handle. No batteries are needed, making it a straightforward, accurate choice for ensuring perfect tightening every time.

Best For: professional machinists and automotive technicians who require precise torque and angle measurements for fastener tightening.

Pros:

- Measures torque angles up to 360 degrees in 2-degree increments for high accuracy

- Durable chrome vanadium steel construction ensures long-lasting performance

- Adjustable arm in two lengths provides versatile application options

Cons:

- Limited to 1/2-inch drive size, may not fit all fasteners

- Only includes one torque angle gauge and wrench, requiring additional tools for other sizes

- No digital readout, relying on manual recognition of measurements

1/2 Inch Torque Wrench Angle Gauge Tool

With its 360-degree adjustable torque adapter, the Inch Torque Wrench Angle Gauge Tool offers precise and reliable measurements for anyone working on automotive or mechanical projects. Its clear, circular scale with 2-degree increments and 10-degree interval markings guarantees accurate readings at a glance. The scale resets to zero easily via the rotating housing, making multiple measurements quick and straightforward. Made of durable carbon steel, it’s built to last and compatible with most cars, RVs, and off-road vehicles. Its simple mechanical design and adjustable arm make it versatile and easy to use, whether for professional repairs or DIY maintenance.

Best For: DIY enthusiasts and professional technicians seeking precise and reliable torque and angle measurements for automotive repairs and mechanical projects.

Pros:

- Provides accurate readings with a clear 360° circular scale in 2-degree increments and 10-degree intervals.

- Durable construction made of high-quality carbon steel ensures long-lasting use.

- Easy to operate with a simple mechanical design, quick reset to zero, and adjustable arm for versatile workspace needs.

Cons:

- May require some initial familiarization with the mechanical operation for new users.

- Limited to 1/2-inch drive interface, which may not fit all torque wrenches or tools.

- Slightly heavier compared to simpler models, which could be less convenient for extended use.

1/2 Digital Torque Wrench Angle Gauge for Rotation and Angle Measurement

If you need precise rotation and angle measurements during torque applications, the Digital Torque Wrench Angle Gauge is an excellent choice. Its 360-degree adjustable adapter makes measuring rotation angles after pre-torque simple and accurate. Made of durable carbon steel, it’s built to last and works well on most vehicles, including cars, motorhomes, and off-road vehicles. The clear scale with graduations allows for quick readings, while the adjustable arm offers flexibility with two length options. Compact and lightweight, it’s easy to carry and store. Plus, zeroing the gauge is straightforward, ensuring you prevent mistakes and achieve perfect tightening every time.

Best For: DIY enthusiasts and professional mechanics needing precise rotation and angle measurements during vehicle maintenance and repairs.

Pros:

- Accurate 360-degree measurement with clear graduations for quick readings

- Durable construction with high-quality carbon steel material ensures long-lasting use

- Compact and lightweight design for easy portability and storage

Cons:

- Customer ratings are moderate at 3.8 out of 5 stars, indicating some users may experience issues

- Price and availability may vary depending on the retailer

- Requires proper calibration to ensure measurement accuracy before use

Performance Tool M210 Torque Angle Gauge w/Flexible Clip Arm

The Performance Tool M210 Torque Angle Gauge stands out for its flexible clip arm, making it an excellent choice for mechanics and DIY enthusiasts who need to tighten head bolts and bearing caps accurately. Its 15-inch flexible shaft, combined with a strong spring clamp and powerful magnet, offers versatile mounting options. The gauge’s easy-to-read 360-degree scale in 2-degree increments ensures precise torque application, helping prevent over-tightening and damage. Made from durable alloy steel with a powder-coated finish, it’s built for reliability. Although some users report issues with the magnet and clip, many find it effective for shop use, especially when modifications are made.

Best For: mechanics and DIY enthusiasts needing accurate torque and angle measurements for head bolts and bearing caps in automotive repair.

Pros:

- Flexible clip arm allows for versatile mounting and positioning.

- Easy-to-read 360-degree dial with 2-degree increments for precise torque application.

- Durable construction from alloy steel with a powder-coated finish ensures longevity.

Cons:

- Some users report weak magnets reducing mounting effectiveness.

- Clip and clamp quality may be subpar, leading to potential failures or need for modifications.

- Limited reviews indicate possible durability issues with certain components over time.

OEMTOOLS 25424 Torque Angle Gauge for Precision Angular Tightening

The OEMTOOLS 25424 Torque Angle Gauge is an excellent choice for professional auto mechanics and serious DIYers who need accurate angular measurements during fastener tightening. Its high-accuracy, analog wheel calibrated in degrees makes it easy to read and precise. The housing allows quick reset to zero, so you can rely on it for multiple uses. Made from durable metal and plastic, it’s built to last and backed by a lifetime warranty. Compatible with 1/2 inch drive tools, it’s perfect for late-model engines and torsion-to-yield fasteners. No batteries needed, making it simple and reliable for automotive, electrical, or home projects.

Best For: professional auto mechanics, serious DIYers, and electricians who require precise angular tightening of fasteners for automotive, electrical, or home improvement projects.

Pros:

- High-accuracy analog wheel calibrated in degrees for easy and precise readings

- Durable construction from metal and plastic with a lifetime warranty

- No batteries required, offering reliable mechanical operation and quick reset to zero

Cons:

- Limited to 1/2 inch drive tools, which may restrict compatibility with other tool sizes

- Analog design may be less precise than digital alternatives for some users

- Customer rating of 3.9 stars suggests some users may experience quality or usability issues

QWORK Torque Angle Gauge with 16.5″ Flexible Clamp Arm

Designed for automotive enthusiasts and professional mechanics alike, the QWORK Torque Angle Gauge with a 16.5″ flexible clamp arm stands out with its magnetic flexible bar, allowing effortless access to hard-to-tighten bolts in tight spaces. Made from durable alloy steel with a powder-coated finish, it offers a clear dial scale with 360° angles in 2° and 10° increments. Its knurled angle knob ensures non-slip adjustments, and it’s compatible with torque wrenches, ratchets, and bending bars. Perfect for tightening head bolts, bearing caps, and interior bolts, it provides precise torque angle measurements in a compact, easy-to-use design.

Best For: automotive enthusiasts and professional mechanics who need precise torque angle measurements in tight spaces.

Pros:

- Features a magnetic flexible bar for easy access to hard-to-tighten bolts in confined areas.

- Made from durable alloy steel with a powder-coated finish for longevity and corrosion resistance.

- Clear dial scale with 360° angles in 2° and 10° increments for accurate readings.

Cons:

- Weighs 0.41 kg, which might be slightly heavy for prolonged handheld use.

- Mechanical operation requires manual adjustments, lacking electronic precision.

- Limited to 1/2 drive size, which may not fit all socket types.

Performance Tool M205 1/2-Inch Torque Angle Gauge Tool

If you’re looking for a budget-friendly option for light-duty torque and angle measurements, the Performance Tool M205 1/2-Inch Torque Angle Gauge Tool might catch your interest. Made from steel with a chrome finish, it offers a durable design suitable for less demanding tasks. The 360-degree angle scale in 2-degree increments helps with precise torque application, and its adjustable arm provides flexibility for hard-to-reach spots. However, some users report reliability issues, like sticking dials or inaccurate readings over time. While it’s inexpensive and lightweight, the build quality and consistency may not meet expectations for frequent or heavy use. Use it cautiously for light jobs.

Best For: DIY enthusiasts or hobbyists seeking an affordable, lightweight torque angle gauge for light-duty tasks and occasional use.

Pros:

- Inexpensive and budget-friendly option for light tasks

- Made from durable steel with a chrome finish for corrosion resistance

- Adjustable arm with two lengths provides flexibility in tight or hard-to-reach areas

Cons:

- Reliability issues with sticking dials and inaccurate readings over time

- Constructed with plastic components that may deform or malfunction after minimal use

- Not suitable for heavy-duty or frequent professional applications due to questionable durability

BYOBYO 1/2 Inch Drive Torque Angle Gauge

For automotive technicians and mechanics seeking precise torque measurements, the BYOBYO 1/2 Inch Drive Torque Angle Gauge offers an excellent solution. Its 360-degree adjustable scale ensures accurate angle readings, essential for proper tightening. Made with durable CRV steel and a tough plastic casing, it’s built to last through rigorous use. Compact and easy to handle, the gauge includes a wrench for immediate use. The knurled L-shaped rod prevents slipping, boosting safety and accuracy. Whether working on engines, chassis, or mechanical components, this gauge simplifies angle adjustments, helping you achieve perfect tightness every time with confidence.

Best For: automotive technicians, mechanics, and DIY enthusiasts requiring precise torque and angle measurements during vehicle repairs and mechanical maintenance.

Pros:

- Durable construction with CRV steel and tough plastic casing for long-lasting use

- 360-degree adjustable scale allows for accurate and versatile angle readings

- Compact design with knurled L-shaped rod enhances safety, grip, and ease of handling

Cons:

- Weighs only 5.6 ounces, which may feel less robust for heavy-duty applications

- Limited to 1/2 inch drive compatibility, less versatile for different drive sizes

- May require calibration or familiarity for precise angle adjustments in complex tasks

1/2 Inch Torque Wrench Angle Gauge Tool

The 1/2 Inch Torque Wrench Angle Gauge Tool stands out as an essential choice for professional mechanics who need to meet precise torque and angle specifications. Its 360-degree adjustable drive torque meter set allows for accurate measurement of fastener turns, ensuring everything is tightened to manufacturer standards. With clear markings in 2-degree increments and 10- and 30-degree intervals, reading the gauge is straightforward. Made from durable metal and plastic, it’s built for repeated use and resistance to wear. Its simple operation makes it easy to achieve perfect tightness every time, making it a reliable tool for any professional setting.

Best For: professional mechanics and auto technicians needing precise torque and angle measurements for vehicle maintenance.

Pros:

- Provides accurate 360-degree measurement with 2-degree increments for precise fastening.

- Made of durable metal and plastic, ensuring long-lasting performance and resistance to wear.

- Easy to read with clear markings and simple operation, facilitating quick and accurate tightening.

Cons:

- May be more expensive than basic torque tools lacking angle measurement features.

- Requires familiarity with torque and angle settings to use effectively.

- The size and design may be less suitable for tight or hard-to-reach spaces in some vehicle models.

Factors to Consider When Choosing a Torque Angle Gauge

When selecting a torque angle gauge, I consider how well it functions with my tools and whether it meets measurement accuracy standards. I also look at its build quality, ease of calibration, and the range and precision of its scale. These factors help make certain I choose a reliable and effective gauge for my needs.

Compatibility With Tools

Choosing a torque angle gauge that fits your tools is essential for accurate and efficient work. I always check that the gauge’s drive size matches my ratchet or wrench, usually 1/2 inch, to ensure a secure fit without needing adapters. Confirming compatibility means the gauge connects firmly and operates smoothly with my existing tools. I also consider whether the drive mechanism suits the fasteners and applications I work with regularly. Additionally, I verify that the measurement scale and increments meet my precision needs for both torque and angle. Finally, I look for a design that allows easy attachment and operation in tight or hard-to-reach spaces. Ensuring compatibility helps prevent inaccuracies and makes my work more efficient.

Measurement Accuracy Standards

Ensuring measurement accuracy is vital for getting reliable torque angle readings. Standards typically require gauges to be precise within 2 degrees to guarantee proper fastener tightening. High-quality gauges must be regularly calibrated and validated against industry benchmarks to maintain this accuracy. The material quality also plays a role; steel or alloy components tend to provide more consistent and stable measurements compared to plastic parts. Regular zeroing and calibration checks are indispensable to keep the gauge within its specified accuracy over time. Additionally, the measurement increments, such as 2° or 10°, impact precision—smaller increments allow for finer control and more accurate torque application. Choosing a gauge that meets these standards helps ensure consistent, reliable results every time you tighten fasteners.

Build Quality and Durability

The build quality and durability of a torque angle gauge are essential factors because they directly affect the tool’s performance and lifespan. High-quality gauges are made from durable materials like chrome-vanadium or alloy steel, ensuring they can withstand frequent use and tough conditions. A polished or powder-coated finish helps resist corrosion, abrasion, and environmental damage, extending the tool’s life. Well-designed gauges feature precise calibration mechanisms and clearly marked scales, maintaining accuracy over time. Reinforced joints and sturdy construction reduce the risk of cracking or bending during demanding jobs. Additionally, protective covers and reinforced housings safeguard internal components, ensuring measurement reliability. Investing in a durable gauge means you’ll have a reliable tool that performs consistently and lasts for years.

Ease of Calibration

When selecting a torque angle gauge, ease of calibration plays a crucial role in ensuring accurate and reliable measurements. A clear, accessible scale marked in 2° increments makes calibration straightforward, saving time and reducing errors. Mechanical gauges often allow simple zeroing by turning or rotating the housing, which doesn’t require tools or complex procedures. A knurled knob or similar adjustment mechanism helps achieve precise calibration, ensuring consistent readings. Some gauges feature quick reset options, making it easier to maintain accuracy over multiple uses. User-friendly calibration procedures are especially important in professional settings where precision is critical. Overall, a gauge that’s easy to calibrate not only boosts confidence in your measurements but also enhances efficiency and reliability during every use.

Range and Scale Precision

Choosing a torque angle gauge with the right range and scale precision can make a significant difference in your work. A wider range allows you to measure larger rotational movements, which is crucial for tasks requiring substantial tightening angles. Precise scales, typically marked in 2-degree increments, help guarantee accurate readings and reduce risks of over- or under-tightening. Quick reference points, like 10 or 30-degree intervals, streamline adjustments during assembly. For delicate or critical fasteners, a fine-scale resolution that detects small angular changes is essential. Overall, the accuracy of the scale directly influences the reliability of your torque application, especially in professional or safety-critical scenarios. Selecting a gauge with suitable range and high scale precision ensures consistent, precise, and safe tightening every time.

Price and Warranty Options

Finding a torque angle gauge that offers the right balance of price and warranty options is essential to making a smart purchase. I recommend comparing prices across various online and offline retailers to find the best deal. Look for products that include a 30-day return policy, giving you flexibility if the gauge doesn’t meet your expectations. Equally important are warranties—aim for ones offering 12 months or even lifetime coverage, especially for manufacturing defects or calibration issues. Some gauges come with warranty support and customer service, which can be a lifesaver if problems arise. Keep in mind, lower-priced options often have limited warranties or shorter return periods, so weigh the cost against the level of protection to ensure you’re covered in the long run.

Frequently Asked Questions

How Do I Calibrate a Torque Angle Gauge for Accuracy?

To calibrate my torque angle gauge accurately, I start by ensuring it’s clean and free of debris. I then set it to zero or the manufacturer’s recommended starting point. Next, I attach it to a calibrated torque wrench or a known standard, gently applying torque while verifying the gauge’s reading. If discrepancies appear, I adjust the gauge according to the manufacturer’s instructions or have it professionally calibrated to maintain precision.

Can Torque Angle Gauges Be Used With Non-Standard Drive Sizes?

Absolutely, torque angle gauges can be used with non-standard drive sizes! I’ve seen these tools handle everything from tiny, precision screws to massive industrial bolts. Just make sure you use the appropriate adapters or attachments designed for your specific drive size. I always double-check compatibility before starting, because using the right setup guarantees accurate readings and prevents damaging your fasteners or the gauge itself.

What Maintenance Is Required to Keep My Torque Angle Gauge Precise?

To keep my torque angle gauge precise, I regularly calibrate it according to the manufacturer’s instructions, usually every few months. I also keep it clean and store it in a protective case to prevent damage. Avoid dropping or exposing it to extreme temperatures. Periodic checks with a known standard help guarantee accuracy, and I always handle it gently to maintain its calibration and performance over time.

Are Digital Torque Angle Gauges More Reliable Than Analog Ones?

Think of digital torque angle gauges like a GPS for your tightening needs—more precise and easier to read. I’ve found them more reliable than analog gauges because they provide instant, clear feedback, reducing human error. Plus, digital models often come with calibration reminders. While analog gauges are sturdy, digital ones tend to be more consistent and user-friendly, especially for complex or frequent tasks.

How Do Environmental Conditions Affect Torque Angle Gauge Performance?

Environmental conditions definitely impact torque angle gauge performance. Extreme temperatures can cause materials to expand or contract, leading to inaccurate readings. Humidity and moisture may affect sensitive components, especially in digital gauges, causing malfunctions. Dust or dirt can interfere with moving parts. I always recommend calibrating your gauge regularly and using it in controlled environments when possible to guarantee consistent, accurate tightening results.

Conclusion

Think of choosing the right torque angle gauge as selecting a trusty compass for a journey. With the right tool in hand, every turn becomes confident and precise, guiding you through the winding roads of maintenance and repair. When you pick the perfect gauge, you’re not just tightening bolts; you’re steering your projects toward success with certainty and control. Let this be your guiding star for flawless, worry-free results every time.