To pass inspections with modified differentials, guarantee you comply with regional regulations and keep detailed records of all modifications and repairs. Use certified materials and conduct thorough external and internal inspections before testing. Perform rigorous performance checks, monitor key metrics, and schedule regular maintenance. Proper cooling and leak prevention are essential, so use high-quality coolers and secure seals. Engaging certified technicians can make all the difference—continue exploring for expert tips to smoothly navigate the process.

Key Takeaways

- Ensure all differential modifications comply with regional ADRs, standards, and obtain necessary safety and environmental certifications.

- Maintain detailed documentation of modifications, parts used, testing, and inspection records for transparency and traceability.

- Conduct thorough external and internal inspections, including fluid analysis and performance testing, to verify safety and functionality.

- Use certified materials and quality components with traceability to meet compliance and durability requirements.

- Engage qualified technicians for expert assessments, routine maintenance, leak prevention, and to prepare comprehensive inspection reports.

Understand Regulatory Requirements for Differential Modifications

To successfully pass inspections with modified differentials, understanding the regulatory requirements that govern these modifications is essential. You must verify your vehicle complies with all relevant regulations, such as ADRs and Australian Standards. Certification is often necessary to confirm that your modifications meet safety and performance standards. Keep in mind that regulations can vary between states, so you need to be aware of regional differences. Modifications should align with industry standards to guarantee safety and reliability. Failing to meet these regulations can lead to legal penalties and safety risks. This means carefully reviewing vehicle standards, environmental rules, and safety certifications. Staying informed about the specific standards your modifications must meet will help you prepare effectively for compliance inspections. Additionally, understanding TikTok Trends can offer insights into popular modifications and compliance tips shared by other enthusiasts. Being aware of industry standards can also help you ensure your modifications are compliant and safe, reducing the risk of inspection failure. Incorporating knowledge from professional advice can further aid in ensuring your modifications meet all necessary requirements, especially considering that regulatory compliance is a critical aspect of vehicle modification safety. Moreover, consulting state-specific regulations can provide clarity on regional legal requirements and streamline your compliance process.

Keep Detailed Documentation of All Modifications and Repairs

Maintaining detailed documentation of all differential modifications and repairs is essential for guaranteeing compliance during inspections. You should record dates, times, and specific changes made, ensuring each modification is authorized by the proper personnel. This helps demonstrate adherence to regulations and prepares you for audits or inspections. Additionally, document all mechanical adjustments and test results, including measurements before and after modifications, testing conditions, and outcomes. Keep a thorough inventory of spare parts used, noting part numbers, sources, and costs to track availability and expenses. Maintain a comprehensive repair history that logs dates, issues, and solutions, helping you anticipate potential problems. Organized, up-to-date documentation ensures inspection readiness, making it easier to verify compliance and address any questions from inspectors efficiently. Furthermore, regularly reviewing your record-keeping processes ensures continued accuracy and completeness. Proper record management practices facilitate quick retrieval of information and support transparency during audits. Transparency in affiliate relationships is also important to disclose if applicable, especially if you are sharing documentation or promotional content related to modifications. Incorporating digital tools and software can further streamline your record-keeping and ensure data integrity. Maintaining accurate records also helps in establishing a clear audit trail, which can be crucial if compliance issues arise.

Use Certified and Approved Materials During Upgrades

Using certified and approved materials during upgrades guarantees your differential system meets all safety and compliance standards. Select UL-listed components for electrical parts, ensuring third-party approval. NEMA-rated enclosures protect against environmental damage, while fire-resistant cables (IEEE 383 tested) prevent fault propagation. For humid or damaged environments, use non-corrosive alloys like 316L stainless or 6061-T6 aluminum. All materials should arrive with batch/test certifications (MTRs) and supplier qualification files demonstrating ISO 9001 or 13485 compliance. Handle sensitive components with ESD-safe procedures and verify copper purity (99.95%+ ASTM B187). Ensure all hazardous substances have accessible SDS, and confirm pressure ratings per ASME standards. Using blockchain-tracked shipments and GSA-approved vendors further guarantees material integrity and traceability during upgrades. Additionally, implementing vertical storage solutions can streamline inventory management and ensure proper handling of critical components. Incorporating material traceability systems helps verify the authenticity and quality of each component throughout the upgrade process.

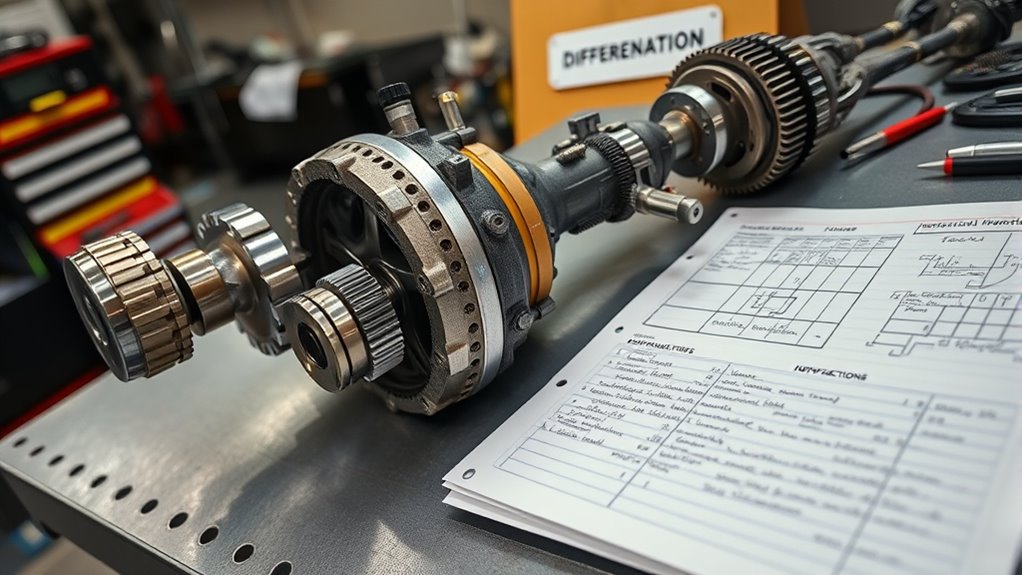

Conduct Thorough External and Internal Inspections Before Testing

Before testing your differential, it’s essential to perform a thorough external and internal inspection to identify potential issues that could compromise performance or safety. Start by visually examining the exterior for signs of wear, damage, or leaks around seals and gaskets. Monitor the temperature to ensure it stays within normal limits, preventing overheating. Check fluid levels and confirm they meet the recommended specifications. Inspect bolts and fasteners, tightening and applying thread locker if needed. Look for excessive wear on moving parts like bearings and gears, and evaluate seal and gasket conditions. Internally, perform oil analysis to detect contamination and wear particles. Inspect gears and bearings for damage, ensuring internal components are properly aligned. Address any leaks, corrosion, or deterioration before proceeding to testing.

Perform Rigorous Functional and Performance Testing

To guarantee your modified differential performs reliably and safely, you need to conduct thorough functional and performance testing. First, verify core operations like torque distribution, gear engagement, and load balancing under normal conditions. Use automated tests for components such as clutches and bearings, employing industry-standard frameworks like pytest. Conduct stress tests simulating extreme scenarios—off-road driving or high-speed cornering—to identify potential failure points. Testing protocols should include detailed inspection of each component’s response under these conditions. Compare pre- and post-modification performance by measuring noise, vibration, and efficiency. For performance, monitor heat dissipation during high loads, assess power loss with dynamometers, and verify axle speed synchronization using telemetry. Additionally, evaluating differential durability under various conditions ensures longevity and safety. Test lubricant effectiveness at different temperatures, ensuring the system’s durability and safety before inspection. Incorporating automotive water spot removers during maintenance can help prevent corrosion that may affect the differential’s longevity and performance. Moreover, performing comprehensive testing on the entire drivetrain system can help detect issues that might not be apparent during isolated component assessments.

Schedule Regular Maintenance and Track Performance Metrics

Establishing a consistent maintenance schedule and diligently tracking performance metrics are essential steps in guaranteeing your modified differential remains reliable and inspection-ready. Follow factory recommendations for fluid changes, typically every 30,000–60,000 miles, but adjust for severe conditions like towing or off-roading, which may require more frequent changes. Verify intervals with your owner’s manual, and consider early fluid replacements at 10,000–20,000 miles to remove debris. Keep detailed records of service dates, mileage, and parts used to demonstrate proper maintenance. Regularly monitor key performance metrics such as fluid condition, temperature, noise levels, and vibrations. Conduct periodic fluid analysis and drive cycle tests to detect early wear. Understanding heat pump efficiency can also help optimize overall vehicle performance and energy use. Maintaining proper differential fluid levels and condition is crucial for preventing wear and ensuring smooth operation. Additionally, tracking performance metrics over time can help identify potential issues before they lead to inspection failures. Incorporating advanced diagnostics can further aid in early detection of problems. Staying informed on inspection requirements and updating your maintenance approach accordingly can further improve your chances of passing. Proper documentation and consistent upkeep help ensure your differential passes inspection without issues.

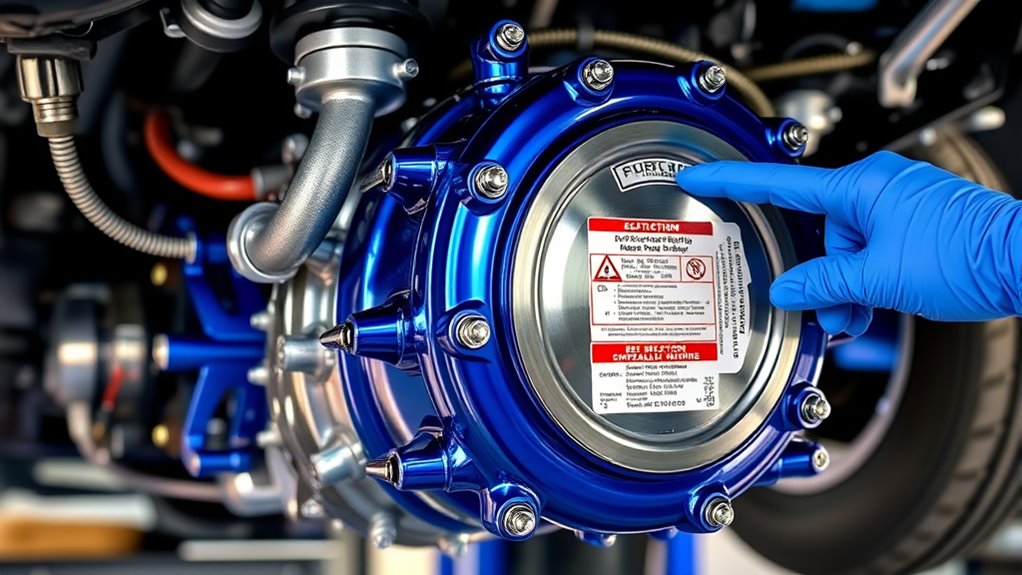

Ensure Proper Cooling and Seal Integrity to Prevent Leaks

Maintaining proper cooling and seal integrity is essential for keeping your modified differential leak-free and operating efficiently. Proper cooling prevents overheating, which can damage seals and cause leaks, while strong seals keep fluids contained under thermal expansion. To achieve this, use high-capacity coolers with correct flow rates and thermostatic controls, and route hoses away from heat sources like exhausts. Select pumps rated for gear oil viscosity, such as Marco pumps handling 140-weight oil. Additionally, check fittings and seals regularly. The table below highlights key components and practices to enhance cooling and seal reliability:

| Component/Practice | Purpose | Tips |

|---|---|---|

| High-capacity coolers | Maintain ideal temperatures | Mount at OEM locations for airflow |

| Thermostatic switches | Control cooling activation | Use Setrab 180°F switch |

| Proper hose routing | Prevent thermal degradation | Keep hoses away from heat sources |

| Silicone-sealed gaskets | Improve seal durability | Replace paper gaskets with metal seals |

| Inline filters | Protect components from debris | Regularly check and replace |

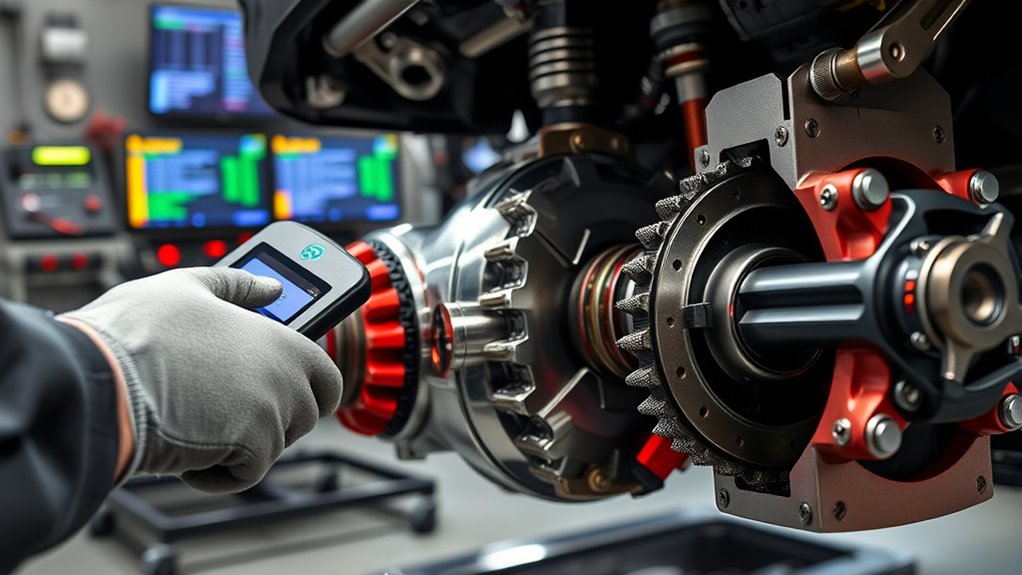

Engage Certified Technicians for Inspection and Verification

Engaging qualified technicians guarantees your modified differential passes inspection and verification processes effectively. ASE-certified professionals bring expert knowledge of drivetrain systems, ensuring thorough evaluations. They conduct detailed digital inspections, examining 30-50 components, including gear wear, bearing tolerances, and seal integrity. Their specialized training in 4×4 and differential systems allows precise assessments of modifications, aftermarket parts, and load capacities. Certified technicians document findings with detailed reports, including photos, videos, and fluid analysis results. They perform non-invasive diagnostics like borescope inspections, thermal imaging, and gear backlash measurements to detect issues early. Their expertise ensures compliance with OEM standards, verifies proper installation, and confirms modifications meet safety regulations. Working with certified technicians not only streamlines the inspection process but also provides peace of mind that your modified differential will pass confidently. Additionally, their understanding of ethical hacking principles can be applied to cybersecurity measures within vehicle systems, ensuring comprehensive security during diagnostics. Recognizing the importance of advanced diagnostic tools, technicians utilize the latest technology to enhance accuracy and efficiency during evaluations. Moreover, familiarity with vehicle modification standards helps ensure all modifications adhere to industry best practices, reducing the risk of failure. Being aware of the aura of your vehicle’s systems can also assist in identifying subtle issues that might otherwise go unnoticed.

Frequently Asked Questions

What Are the Common Signs of Differential Failure During Inspection?

During inspection, you’ll notice common signs of differential failure like unusual noises such as whining, grinding, or clunking during driving. Look for fluid leaks, including oil puddles or low fluid levels, and check for contaminated or degraded fluid. Vibration or shuddering while driving, uneven tire wear, and handling irregularities like resistance during turns also point to differential issues. Addressing these signs early helps prevent further damage and costly repairs.

How Often Should Modified Differentials Be Inspected for Compliance?

You should inspect your modified differential for compliance regularly, ideally every 3,000 to 5,000 miles or as recommended by your mechanic. Keep in mind, the frequency depends on your driving conditions and modifications. Always consult your owner’s manual or contact the manufacturer for specific schedules. Regular inspections by authorized mechanics ensure your vehicle stays compliant with safety standards and avoids legal issues, helping maintain peak performance.

What Are the Best Practices for Documenting Differential Modifications?

Did you know that clear documentation reduces audit rejections by up to 30%? To effectively document differential modifications, use precise language to avoid ambiguity, link changes to specific needs, and follow standardized terminology. Incorporate checklists and templates, guarantee version control, and include timestamps. Regularly review and update records, involve specialists when needed, and maintain an audit trail to demonstrate compliance and support outcomes.

Which Materials Are Preferred for Durable Differential Upgrades?

When choosing materials for durable differential upgrades, you prefer options like cast iron for its strength and cost-effectiveness, steel and chromoly steel for their high durability, and aluminium for weight savings and corrosion resistance. These materials offer a balance of strength, longevity, and performance. Your goal is to select materials that withstand demanding conditions, guarantee safety, and meet regulatory standards, making your differential reliable and inspection-ready.

How Can I Verify if My Differential Modifications Meet Safety Standards?

Your safety depends on this more than your daily commute! To verify if your differential modifications meet safety standards, start by reviewing all documentation, including material certifications and compliance tests. Conduct thorough leak checks, ensure fluid levels are correct, and perform load and thermal stress tests. Confirm the modifications don’t alter factory geometry, and get third-party validation from accredited labs. These steps guarantee your modifications are safe and inspection-ready.

Conclusion

Remember, your modified differential is like a trusted compass guiding your vehicle’s journey. By staying compliant and meticulous, you steer clear of pitfalls and ensure smooth sailing. Keep detailed records as your map, certified parts as your compass needle, and regular checks as steady stars guiding you home. When you treat your modifications with care and attention, you’ll navigate inspections confidently, turning your vehicle’s power into a symbol of responsible craftsmanship and pride on every road ahead.