Nitrous oxide systems boost your tuned car’s performance by releasing extra oxygen into the engine, which fuels more power and faster throttle response. They also produce a cooling effect that densifies intake air, leading to more efficient combustion and higher horsepower. By choosing the right system and tuning properly, you can achieve instant acceleration and significant power gains while maintaining reliability. Keep exploring to discover how to maximize these benefits safely and effectively.

Key Takeaways

- Nitrous oxide releases extra oxygen during combustion, increasing power output and engine efficiency.

- It cools intake air, densifying it for better combustion and reducing engine heat stress.

- Vaporization of nitrous enhances fuel burning, leading to higher torque and acceleration.

- Proper system tuning ensures safe power gains without risking engine damage.

- Upgraded fuel and cooling systems support increased power levels and system reliability.

Understanding the Chemical Composition and Basic Principles of Nitrous Oxide

To understand how nitrous oxide enhances engine performance, it’s essential to first grasp its chemical composition and basic principles.

Nitrous oxide, or N₂O, is a colorless, sweet-tasting gas with a molecular weight of 44.013. It contains two nitrogen atoms and one oxygen atom, bonded together with only two bonds.

You prepare it through reactions involving zinc and dilute nitric acid or hydroxylamine hydrochloride with sodium nitrite. These chemical reactions highlight its chemical synthesis processes which are crucial for safe production and application.

In physical form, it’s non-flammable and used as an anesthetic in medical settings, as well as in food processing and automotive performance.

Handling requires care due to potential hazards like respiratory issues and cognitive impairment. Its Chemical stability is a key factor in its safe storage and handling.

How Nitrous Oxide Boosts Power Through Oxygen Release and Cooling Effects

Nitrous oxide boosts engine power primarily by releasing oxygen and providing a cooling effect in the intake system. When it transforms from liquid to gas, it enriches the air mixture, enabling more efficient combustion. This process delivers a few key benefits: 1. It supplies extra oxygen, allowing your engine to burn more fuel and increase power. 2. The cooling effect from vaporization cools the intake air, making it denser and improving combustion efficiency. 3. The cooler, oxygen-rich mixture reduces overheating risks during high-performance driving. Additionally, understanding the benefits of performance upgrades such as cold air intakes and exhaust systems can further optimize your vehicle’s tuning potential. This combination of oxygen release and cooling enhances power output markedly. The denser air and improved combustion mean higher horsepower and torque. Proper system setup maximizes these effects while protecting your engine from heat and stress. Incorporating proper tuning techniques ensures you get the most out of your nitrous system while maintaining engine longevity.

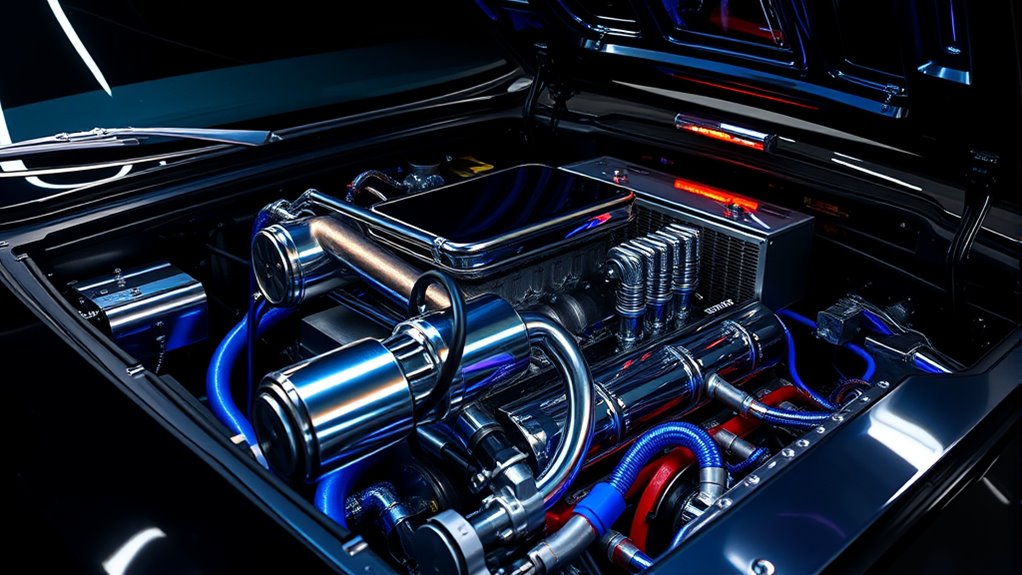

Different Types of Nitrous Systems and Their Suitability for Various Engines

Different types of nitrous systems are designed to meet various engine setups and performance goals, offering options that range from simple upgrades to highly precise tuning tools.

Dry systems add fuel through the engine’s injectors, making them suitable for fuel-injected engines and offering quick, straightforward installation. Since they modify the existing fuel system or increase fuel pressure, they can be easily integrated into many setups. They are popular among enthusiasts seeking reliability and ease of use.

Wet systems introduce both nitrous and fuel directly into the intake, fitting both carbureted and fuel-injected setups. This method allows for more precise fuel delivery and helps prevent engine damage caused by lean conditions.

Direct-port systems inject nitrous and fuel directly into each cylinder, providing the most tuning flexibility and performance, but are complex to install. They are often used in racing applications where maximum control and power are required.

For carbureted engines, wet systems are common, especially with spreadbore carburetors. These systems are appreciated for their simplicity and effectiveness in carbureted setups.

Fuel-injected engines can utilize dry, wet, or direct-port systems, with direct-port offering the highest precision. The selection depends on the desired performance level and the complexity of installation.

Your choice depends on your engine type, tuning goals, and budget. Considering the specific engine setup and intended use will help determine the most suitable nitrous system.

Performance Gains: From Horsepower to Instant Acceleration

Harnessing nitrous oxide can produce dramatic performance gains by substantially boosting horsepower and torque almost instantly. You’ll notice a quick surge in power, transforming your driving experience. Here’s what to expect:

- Horsepower boost: Depending on the system and engine, gains can range from a few to hundreds of horsepower.

- Torque increase: This results in improved acceleration, making your car feel more responsive.

- Immediate power: Unlike other mods, nitrous provides a rapid burst of energy, perfect for quick starts and drag racing.

The extra oxygen from nitrous also enriches the air-fuel mixture, enhancing combustion. AI advancements in safety monitoring can help develop more reliable and secure nitrous systems, reducing risks during use. The cooling effect further improves efficiency, helping your engine handle the increased power confidently. Additionally, understanding engine tuning principles can optimize how your vehicle responds to nitrous injection for safer and more effective performance.

Tuning and Compatibility: Ensuring Safety and Optimal Functionality

To guarantee safety and maximize performance, proper tuning and compatibility checks are essential before activating your nitrous system.

Start by monitoring bottle pressure, keeping it between 900-1000 psi, and ensure the temperature stays between 75-95°F for consistent flow. Use pressure gauges and bottle warmers in cold conditions to maintain ideal pressure.

Check engine components—pistons, rods, and bearings—to handle increased power, especially on high-mileage engines. Nitrous oxide releases oxygen during combustion at ~300°C, increasing power. Regular inspection of these parts can prevent potential failures under increased stress.

Adjust ignition timing by 1-2 degrees per 50hp added, and switch to nitrous-specific spark plugs to prevent pre-ignition. Proper engine tuning procedures are vital for maximizing performance and protecting your engine’s longevity.

Set activation to WOT and use progressive controllers to control power spikes.

Match nitrous and fuel jets carefully, maintaining an AFR of 11:1–12:1, and inspect plugs post-run for signs of detonation, ensuring safe, reliable performance.

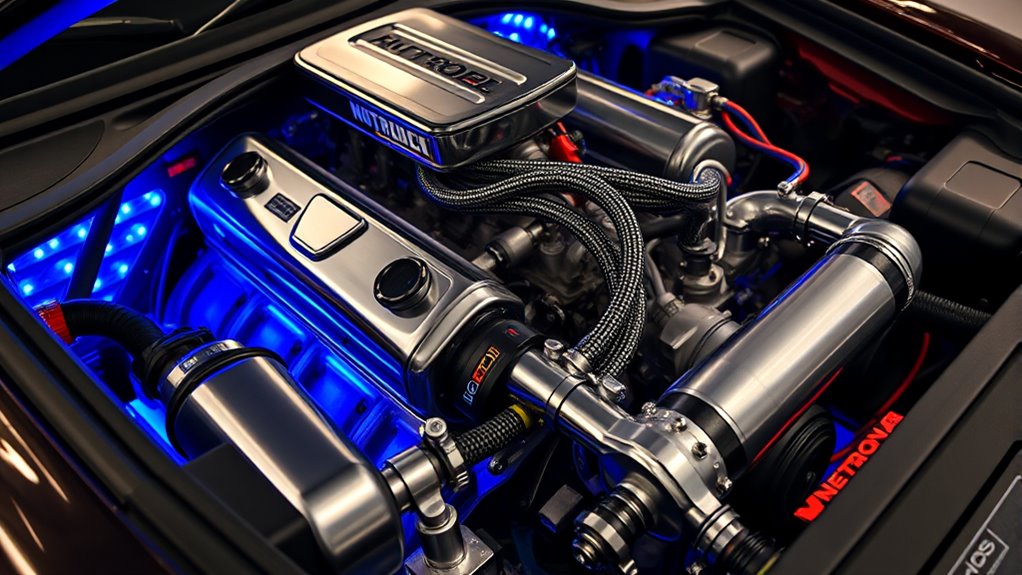

Upgrading Fuel and Cooling Systems for Nitrous-Enhanced Engines

When upgrading your fuel and cooling systems for a nitrous-enhanced engine, ensuring sufficient fuel delivery and effective temperature management is crucial for safe and reliable performance.

First, you should consider installing high-flow fuel pumps to match the increased oxygen from nitrous.

Second, upgrading fuel injectors with higher flow rates prevents lean conditions during nitrous activation.

Third, an adjustable fuel pressure regulator helps maintain ideal fuel-to-nitrous ratios, ensuring consistent power delivery.

For cooling, dual electric fans or high-capacity radiators manage heat buildup from higher combustion temperatures.

Water/methanol injection lowers intake air temperature and reduces detonation risk.

Proper tuning of the fuel system is essential to prevent engine damage during nitrous use. These upgrades keep your engine running smoothly, preventing heat-related issues and ensuring the fuel system supplies adequate fuel for the added power from nitrous.

Proper Installation and Maintenance Practices for Reliability and Safety

Proper installation and maintenance are essential to guarantee your nitrous system operates safely and reliably. Start by selecting high-quality components like solenoids and fuel lines to prevent failures. Confirm wiring and electronic connections are correct for consistent activation, and integrate the system with your ECU for precise control. Using a dedicated controller or ECU integration ensures accurate timing and safe operation. Use proper flow control to maintain steady nitrous delivery and verify material compatibility to prevent corrosion. Always have a professional install your system and perform safety inspections afterward to check for leaks or damage. Regularly inspect lines and fittings, clean solenoids, check system pressure, and monitor the ECU for issues. Properly tuning the ECU for activation points and system testing will help keep your setup safe and performing at its best.

Customization Options to Match Specific Performance Goals

Customizing your nitrous system to match your specific performance goals involves selecting the right components and adjusting settings for ideal power delivery. First, choose between wet, dry, or direct port kits, depending on your engine type and desired power. Second, set your nitrous “shot” size, typically from 50 to 150+ horsepower, based on durability and performance targets. Third, fine-tune flow control with progressive controllers that stage nitrous delivery according to RPM or throttle position, optimizing power and traction. Additionally, integrate with your engine management system by adjusting ignition timing and fuel enrichment to prevent detonation and maintain safe operation under nitrous load. Proper tuning is essential for safety and maximum performance, and working with experienced technicians or utilizing detailed technical resources can help achieve optimal results. These customization options guarantee your system delivers consistent, reliable performance tailored specifically to your car’s capabilities and your driving goals.

Monitoring Engine Health During Nitrous Oxide Use

Monitoring engine health during nitrous oxide use is essential to prevent damage and guarantee peak performance. You should rely on engine gauges to track exhaust gas temperatures (EGTs) and confirm the engine isn’t overheating. Exceeding safe EGT levels can cause engine components to fail. Pressure sensors are critical for maintaining proper bottle pressure, avoiding underfeeding or overfeeding the system. Fuel sensors help you monitor fuel supply, preventing the engine from running too lean or rich. Advanced air/fuel ratio controllers, like the Maximizer 5, adjust fuel delivery based on nitrous injection. System alarms provide real-time alerts for sudden drops in fuel flow or rising EGTs. Inadequate monitoring risks engine overheating, lean conditions, or system failure. Regular checks, sensors, and alarms are essential to keep your engine safe and performing at its best during nitrous use.

Frequently Asked Questions

Can Nitrous Oxide Damage My Engine if Used Improperly?

Yes, nitrous oxide can damage your engine if you use it improperly. If you install it poorly, run lean mixtures, or have incorrect ignition timing, you risk engine damage like overheating or component failure.

To prevent this, guarantee proper system design, installation, and maintenance. Keep the engine in good condition, use conservative settings, and monitor performance.

When used correctly, nitrous can boost power without harming your engine.

How Do I Determine the Right Nitrous System Size for My Car?

Did you know that choosing the right nitrous system size can boost your engine’s horsepower by up to 150%?

To determine the correct size, consider your engine’s displacement, power goals, and existing modifications. You’ll want a system that matches your fuel delivery capacity and flow rates, ensuring safe operation.

Always factor in your air/fuel ratio and monitor system performance to make ongoing adjustments for suitable, safe performance.

Is Nitrous Oxide Legal for Street Use in All Regions?

You might wonder if nitrous oxide is legal for street use everywhere. Legality varies a lot depending on where you are.

Federal laws allow it for industrial and medical uses, but recreational or automotive use isn’t explicitly permitted.

State laws differ widely—some ban recreational use, others have strict regulations, and a few are more lenient.

Always check your local and state laws before installing or using nitrous systems on your street-driven car.

How Often Should I Service My Nitrous Oxide System?

Think of your nitrous system like a high-performance engine — it needs regular checkups to run smoothly. You should perform monthly functional checks, inspecting flowmeters, valves, and hoses for leaks.

Every two years, get a full service or flowmeter inspection. Don’t forget to verify safety alarms every six months and analyze the gas mixture annually.

Regular maintenance keeps your system safe, reliable, and ready for that next adrenaline rush.

What Are the Signs of Engine Stress During Nitrous Oxide Activation?

During nitrous oxide activation, you might notice engine stress signs like knocking or pinging sounds, which indicate abnormal combustion. You could feel sudden power fluctuations or hear exhaust popping, signaling strain.

Other signs include increased engine temperature, fluid leaks, or error codes flashing on your ECU. If you observe these, it’s essential to check your system immediately, as continued stress can cause severe engine damage.

Conclusion

By understanding how nitrous oxide systems work and properly integrating them into your car, you can substantially boost performance and acceleration. Did you know that a well-tuned nitrous setup can increase horsepower by up to 150%? Just remember to prioritize safety, upgrade your fuel system, and monitor engine health closely. With the right approach, you’ll open impressive gains and enjoy a thrilling driving experience without compromising reliability.