To port and polish your Dodge Charger Super Bee, start by carefully disassembling the cylinder head and inspecting the ports for any damage. Shape and gasket-match the intake and exhaust ports to improve airflow, blending progressions smoothly into the runners. Then, use proper polishing techniques to create a flawless finish, ensuring no high spots or imperfections remain. Proper reassembly and testing complete the process. If you keep going, you’ll learn detailed steps to maximize your engine’s performance.

Key Takeaways

- Match and blend intake and exhaust ports to gasket contours, maintaining OEM dimensions with proper flow transitions.

- Use carbide burrs and polishing tools to smooth port surfaces, ensuring a flawless, high-flow finish.

- Maintain port symmetry within 2% and optimize port floor-to-ceiling ratios for maximum airflow.

- Carefully reassemble components, torque gaskets and seals to manufacturer specs, then perform leak and performance tests.

- Incorporate safety measures and organized workflow throughout the porting and polishing process for best results.

Preparing Your Dodge Charger Super Bee for Port and Polish

Before beginning your port and polish work on the Dodge Charger Super Bee, establishing a safe and organized workspace is essential. Set up in a well-ventilated area to control dust and fumes, and use tarps or mats to contain debris for easy cleanup. Secure your cylinder head or throttle body firmly on a stable workbench with vice grips. Ensure proper lighting to clearly see port interiors and identify defects. Wear safety gear, including gloves, goggles, and a respirator, to protect against metal particles and fumes. Keep a fire extinguisher nearby, especially when working near fuel components. Gather all necessary tools, such as carbide burr bits, Dremel sanding attachments, and high-grit polishing bits. Utilizing appropriate safety precautions can significantly reduce risks during the process. Proper workspace organization helps streamline the workflow and prevents accidents. With a clean, safe workspace, you’ll set the foundation for a precise and effective port and polish process. Implementing data-driven strategies can help you measure progress and optimize your results throughout the process.

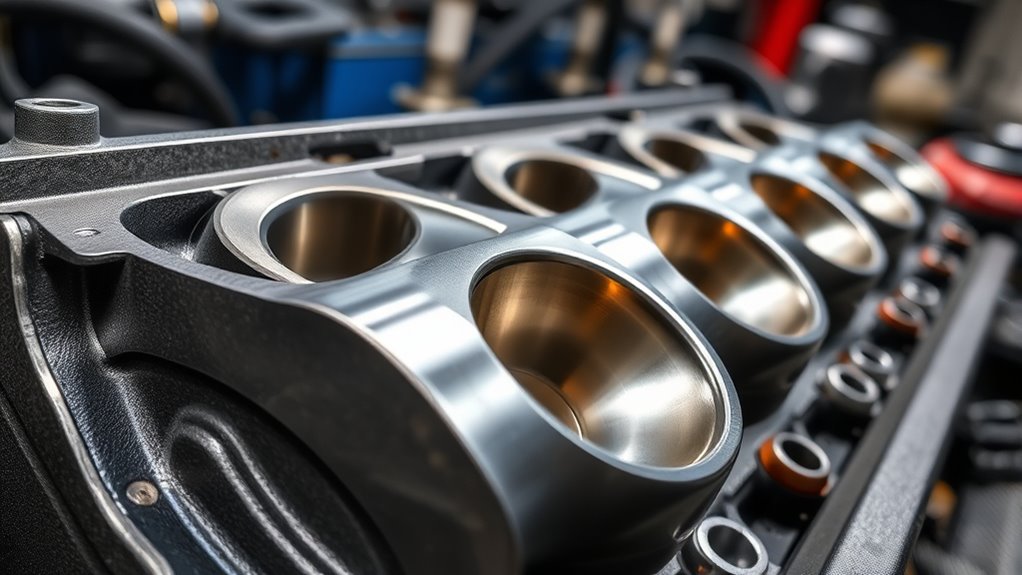

Disassembling and Inspecting the Cylinder Head

Disassembling and inspecting the cylinder head is a critical step that requires careful preparation and attention to detail. Begin with a visual inspection to check for casting defects before disassembly. Remove external components like intake and exhaust studs first to prevent snags and make head removal easier. Use proper tools, such as a soft-faced hammer, to gently remove stuck parts without damage. Organize all disassembled parts in labeled containers for easy reassembly. During removal, check for signs of wear, cracks, damage, and corrosion on components, especially port surfaces and threads. Remove the inspection cover, rocker arms, and valves carefully, inspecting each for wear or debris. This thorough process ensures you identify issues early, setting the stage for effective porting and polishing later.

Shaping and Gasket Matching the Intake and Exhaust Ports

Once you’ve inspected and cleaned the cylinder head components, shaping and gasket matching the intake and exhaust ports guarantees ideal airflow and performance. Start by aligning the ports with the gasket contours, making certain you stay within OEM outer dimensions and maintain a 1/8″ buffer between port edges and gasket boundaries. Blend transitions 1-2″ into the runners to prevent turbulence and verify the shape with machinist dye, removing high spots. Use cartridge rolls to blend short-side radius curves, maintaining a concentric cross-sectional progression from plenum to valve seat. Keep the floor-to-ceiling height ratio at 0.85-0.90:1, optimizing flow velocity. Ensure port symmetry within 2%, and verify the smoothness of transitions. Proper gasket matching and shaping maximize airflow, boosting performance and efficiency for your Super Bee. Additionally, vibrational flow techniques can help optimize airflow dynamics for even better performance. Incorporating flow dynamics principles can further refine port shapes and improve overall engine breathing. Regularly inspecting for airflow turbulence during porting can help identify areas needing further smoothing for optimal results. Implementing these airflow management strategies can significantly enhance the engine’s power output and responsiveness. Paying attention to port consistency ensures uniform flow characteristics across all cylinders, further optimizing performance.

Achieving a Flawless Finish With Polishing Techniques

Achieving a flawless finish with polishing techniques requires meticulous preparation and careful execution to guarantee ideal airflow and performance. Start by inspecting the surface for defects, mold rings, or imperfections. Rinse and dry thoroughly with a foam cannon, scrub pad, and blower to remove contaminants. Use 600-grit wet sandpaper to smooth surfaces, then activate suds with fresh soap and scrub for residue-free results. Select the right tools—carbide bits, rotary tools, and polishing compounds—ensuring safety gear is worn. Progression from low to high grit, focusing on defect removal and uniform material removal with crosshatch patterns. Use high-grit bits with circular motions and apply compounds carefully. Maintaining proper color accuracy throughout the process ensures the final polished surface reflects true color, enhancing the overall quality of the finish. Incorporating proper eye protection is essential when working with polishing equipment to prevent injury. Additionally, ensuring proper airflow during polishing can improve the effectiveness and safety of the process. Good sound science principles underpin sound techniques for vibration and resonance control during polishing. Proper ventilation also helps dissipate fumes and dust generated during polishing, contributing to a safer workspace.

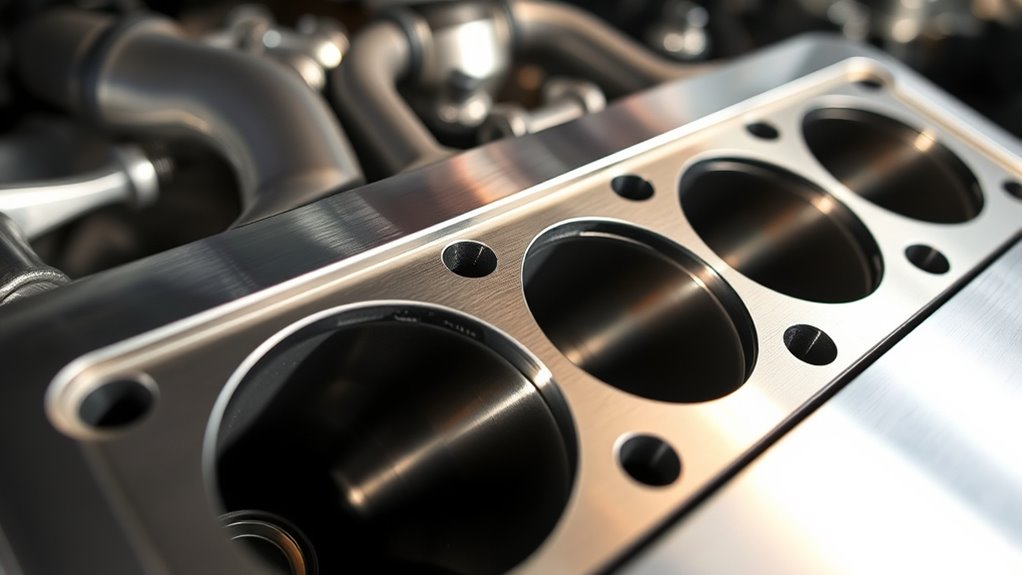

Reassembling, Testing, and Final Checks

Reassembling, testing, and final checks are crucial steps to guarantee your ported Dodge Charger Super Bee performs at its best. Carefully inspect gaskets and seals for damage before reassembly. Properly align and install cylinder heads with new gaskets, then torque manifolds and intakes per specifications. Reattach valves, lifters, and replace timing components if needed. Secure the intake manifold, exhaust headers, and connect the exhaust system to prevent leaks. Install breather and PCV systems for smooth operation. After reassembly, start the engine to check for leaks and unusual noises. Perform leak-down, compression, and load tests to confirm internal integrity. Understanding the resources and tools available can assist in troubleshooting any issues that arise during testing. Additionally, maintaining proper sleep hygiene can help ensure optimal cognitive function during the testing process and accurate diagnostics. Incorporating diagnostic equipment can further streamline identifying potential problems early. Staying informed about the latest automation technologies can also aid in diagnosing and optimizing engine performance. Consulting the repair manual specific to the Dodge Charger Super Bee can provide detailed specifications and procedures. Finally, adjust idle, verify the cooling and fueling systems, inspect electrical connections, and take the car for a drive to ensure peak performance.

Frequently Asked Questions

How Much Horsepower Gain Can I Expect After Porting My Charger Super Bee?

You’re wondering how much horsepower you can gain after porting your charger Super Bee. Typically, mild porting adds around 10-15 HP, while aggressive race porting can boost power by 20-30 HP, especially at higher RPMs. When combined with supporting mods like ECU tuning and upgraded components, you might see total gains of 20-50 HP. Remember, actual results depend on your build and proper installation.

What Are the Common Mistakes to Avoid During Porting?

When porting, you need to avoid common mistakes that can hurt performance. Don’t skip flow bench testing or focus only on flow rates; air velocity matters too. Use proper tools and guarantee ports align correctly to prevent turbulence. Be cautious with polishing—too smooth surfaces can harm fuel vaporization. Remember, bigger isn’t always better, and customize your approach for your specific engine to maximize gains.

Can Porting Affect Emissions or Legality?

You’re walking a tightrope when it comes to porting—one misstep can tip the balance. Porting can affect emissions and legality if it increases pollutants beyond legal limits, especially without proper tuning. You need to stay compliant by understanding regional regulations, keeping detailed records, and ensuring your modifications don’t backfire at inspections. Proper adjustments and documentation help keep your engine legal and emissions in check, avoiding costly fines.

How Long Does a Typical Port and Polish Process Take?

The typical port and polish process takes several weeks, depending on your skill level and the engine’s complexity. You’ll spend time preparing, examining, grinding, and polishing each cylinder head carefully. Rushing can cause damage, so it’s essential to be precise. If you choose CNC machining, the process speeds up considerably, but manual work demands patience and attention to detail, ensuring ideal airflow and performance gains.

Is Professional Porting Necessary for Optimal Performance?

You might wonder if professional porting is essential for peak engine performance. While DIY porting can improve airflow, it often risks uneven material removal, turbulence, and structural weaknesses that hurt power. Professional porting guarantees precise, consistent results with CNC or specialized tools, optimizing airflow, reducing backpressure, and maintaining engine integrity. If you’re aiming for maximum gains and reliability, investing in expert porting is the smart choice.

Conclusion

By porting and polishing your Dodge Charger Super Bee’s cylinders, you’re enhancing airflow and boosting performance. Did you know that properly ported engines can increase horsepower by up to 20%? That’s a significant gain for such a powerful vehicle. Taking the time to carefully disassemble, inspect, shape, and polish guarantees maximum efficiency and reliability. So, invest in this meticulous process—it’s the way to unlock your Super Bee’s full potential on the road.