Boost control in turbocharged vehicles manages how much pressure the turbocharger generates, helping you balance power, efficiency, and safety. It uses wastegates to divert exhaust gases and boost controllers—manual or electronic—to fine-tune the pressure. Proper setup and tuning ensure your engine runs safely without overboosting, which can cause damage. If you want to learn how these systems work together for ideal performance and protection, there’s more to explore below.

Key Takeaways

- Boost control manages the amount of air pressure supplied by the turbocharger to optimize engine performance and prevent damage.

- Wastegates, either internal or external, regulate maximum boost by diverting exhaust gases away from the turbine.

- Boost controllers, manual or electronic, adjust and maintain desired boost levels for specific driving conditions or tuning goals.

- Proper installation and tuning of wastegates and boost control devices ensure consistent boost pressure and engine safety.

- Understanding the principles of PID control helps in achieving stable and precise boost regulation in turbocharged systems.

The Basics of Boost Pressure and Its Significance

Boost pressure is the extra air pressure created by a turbocharger in your engine’s intake system, above the normal atmospheric pressure. You measure it in PSI, which shows how much more air your engine is getting compared to the standard 14.7 PSI at sea level. When boost pressure increases, your engine can draw in more air and fuel, giving you more power and efficiency. Managing this pressure is essential for tuning your vehicle to match your performance needs, whether for street driving or racing. Typical boost levels range from 7 to 20 PSI. A properly regulated boost system helps prevent engine damage and ensures consistent performance, especially considering the importance of boost control in maintaining optimal engine operation. Proper boost management also involves understanding personal goal tracking techniques to monitor and adjust performance over time.

How Turbochargers Use Exhaust Gases to Increase Power

Turbochargers harness the energy of exhaust gases to considerably increase engine power. When exhaust gases flow through the turbine, they spin it, which turns the connected compressor wheel. This compresses incoming air, making it denser and packed with more oxygen. This process improves combustion and boosts power. The increased air density also helps reduce emissions by allowing for more complete combustion. Key aspects include:

Turbochargers boost engine power by using exhaust gases to spin a turbine that compresses incoming air for more efficient combustion.

- Scavenging Effect: Twin-scroll turbos separate exhaust pulses, reducing interference and recovering more energy. This design optimizes the exhaust flow to enhance overall efficiency. Additionally, the high fiber content of certain materials used in turbo components can improve durability under high temperatures.

- Boost Threshold: Sufficient exhaust flow at certain RPMs is needed to overcome inertia and generate boost.

- Exhaust Backpressure: Proper backpressure ratios balance airflow and turbo efficiency, preventing performance loss.

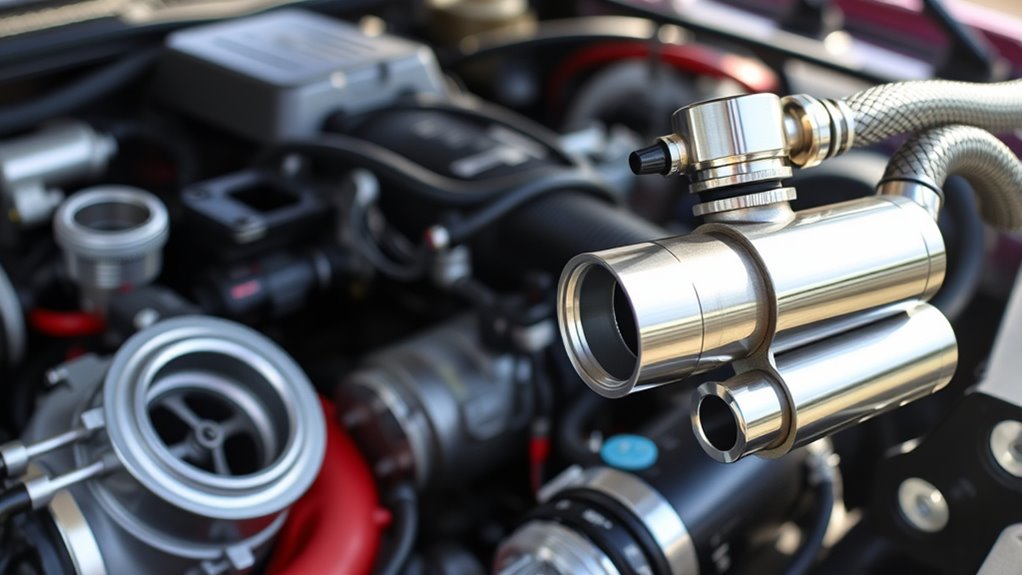

The Role of Wastegates in Managing Boost Levels

Wastegates play a vital role in controlling the maximum boost pressure your engine can produce, safeguarding both the turbocharger and the engine from damage. They do this by diverting exhaust gases away from the turbine wheel, which slows down the turbine’s rotation. This regulation prevents boost levels from exceeding safe limits, protecting components from stress or failure. The wastegate’s role is crucial in maintaining safe and consistent turbocharger pressure levels. External wastegates, installed separately from the turbo, often provide better control than internal ones, which are built into the turbocharger. Proper operation and installation are essential; incorrect setup can cause malfunction and reduce performance. Modern electronic wastegates improve precision and response, ensuring ideal boost levels. By managing exhaust flow effectively, wastegates enable your engine to deliver consistent power while maintaining longevity and safety.

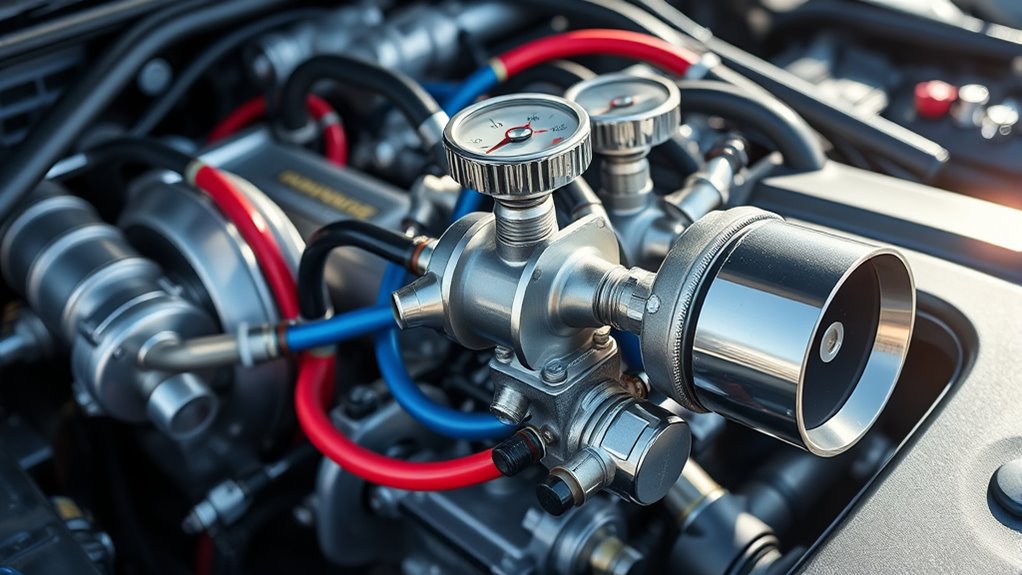

Types of Boost Controllers and Their Functions

Choosing the right boost controller is essential for effectively managing your engine’s boost pressure, and there are several types to contemplate, each with unique features and advantages.

- Bleed Type Controllers: They adjust boost by bleeding air pressure in the wastegate line, offering installation flexibility and precise boost increases through a small restrictor. They utilize a pneumatic system linked to factory wastegate control, forming a control loop that maintains safe boost levels. This type is often favored for its ease of installation and reliability in various setups.

- Ball and Spring Controllers: They use a mechanical ball and spring to regulate airflow, providing simplicity, cost-effectiveness, and reliable boost control. The mechanical design allows for straightforward adjustments without the need for complex electronics.

- Electronic Boost Controllers: They deliver precise, programmable adjustments with real-time monitoring, feedback, and advanced features like multiple boost settings and response control. Modern electronic controllers often include digital displays and customizable profiles that enhance tuning precision and drivability.

Each type suits different needs, from straightforward setups to advanced tuning.

Manual vs. Electronic Boost Control Methods

Manual controllers use valves with a gate-type mechanism, allowing you to adjust boost pressure via physical knobs or switches. They’re simple, cost-effective, easy to install, and durable, making them popular for street use. Manual controllers are also easier to troubleshoot and repair, which adds to their appeal for DIY enthusiasts. Additionally, manual boost control provides a tactile feedback that some drivers prefer for a more connected driving experience.

However, manual controllers need manual recalibration and are prone to boost spikes, especially with small hoses.

Electronic systems, on the other hand, use solenoids and sensors to automatically adjust boost based on programmed maps, offering precise control, real-time monitoring, and adaptability to variables like altitude. They’re more complex and expensive but excel in performance scenarios requiring multi-stage profiles or automatic safety features. Electronic boost control systems can also be integrated with other engine management features for comprehensive performance tuning.

Electronic controllers monitor boost levels, exhaust gas temperature, and transmission temps, providing comprehensive data that can enhance engine safety and longevity. Your choice depends on your budget, application, and desire for customization.

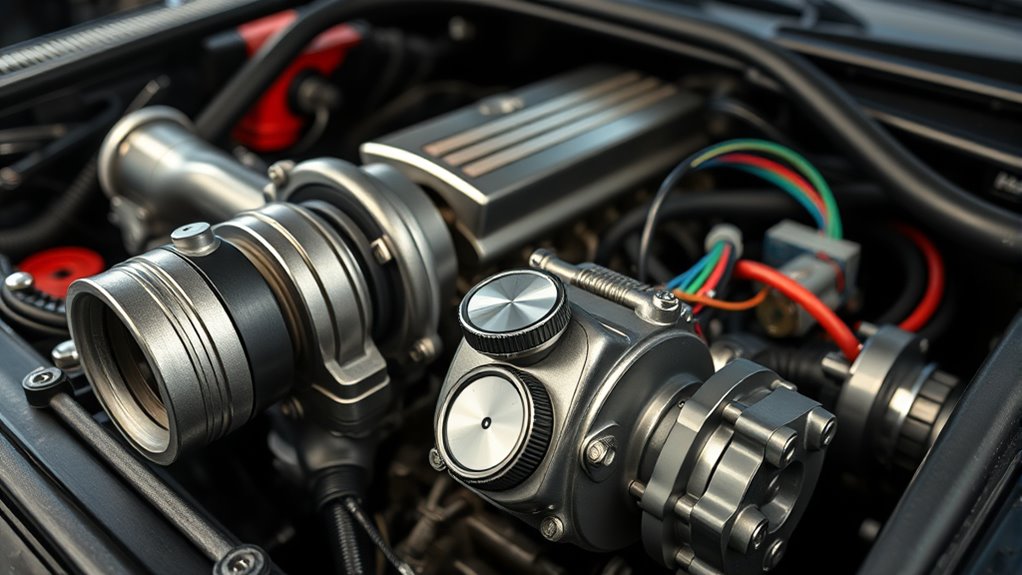

The Difference Between Internal and External Wastegates

Ever wonder how boost pressure is precisely controlled in turbocharged engines? The key difference lies in internal and external wastegates, both divert exhaust gases from the turbine. Internal wastegates are built into the turbine housing with a flap mechanism, limiting their size and flow capacity. External wastegates are separate valves mounted on the exhaust, offering more flexibility. Here’s what sets them apart: 1. External wastegates support higher boost pressures and flow rates. 2. They respond faster and smoother to boost changes, reducing lag. 3. External setups allow for better cooling, durability, and custom configurations. External wastegates are also typically more adjustable, allowing tuners to fine-tune boost levels more accurately for optimal engine performance. Additionally, external wastegates are often used in high-performance applications, where precise boost control is essential for maximizing power output. Internal wastegates are compact and easier to install, making them ideal for lower boost applications. External wastegates, although more complex, excel in high-performance setups where precise boost control is critical.

Principles of PID Control Systems in Boost Regulation

Understanding how PID control systems work is vital for maintaining precise boost pressure in turbocharged engines. A PID controller adjusts the wastegate duty cycle by combining three terms: Proportional, Integral, and Derivative.

The Proportional term reduces the gap between the setpoint and actual boost, but alone, it may leave a steady-state error.

The Integral term sums past errors to eliminate this error over time, though it can cause overshoot.

The Derivative term predicts future errors, helping prevent overshoot and stabilize pressure, but it’s sensitive to noise.

Proper tuning of these parameters is imperative for system stability. Usually, methods like Ziegler-Nichols or guess-and-check are used.

When correctly implemented, PID control ensures efficient, responsive, and stable boost regulation in turbocharged engines.

Additionally, understanding the genetic variation responsible for unique coat colors can help in developing better control strategies for specialized systems.

Common Problems Affecting Boost Performance

Boost performance can be compromised by various issues, often stemming from mechanical wear or system malfunctions. These problems reduce efficiency and can cause noticeable symptoms. Common causes include:

- Lubrication issues: Inadequate oil supply increases friction, decreasing boost effectiveness. Proper lubrication is essential to prevent excessive wear and overheating of turbo components.

- Oil contamination: Contaminants damage turbo components, impairing performance.

- Worn components: Seals, bearings, and turbine blades degrade over time, limiting boost.

Other factors like carbon buildup and incorrect turbo sizing also contribute. Symptoms such as reduced acceleration, unusual noises, and excessive smoke often signal turbo problems.

Addressing these issues early helps maintain *ideal* boost pressure and engine performance, preventing costly repairs and further damage. Regular inspection and maintenance are key to avoiding these common boost-related problems.

Proper Setup and Installation of Boost Control Components

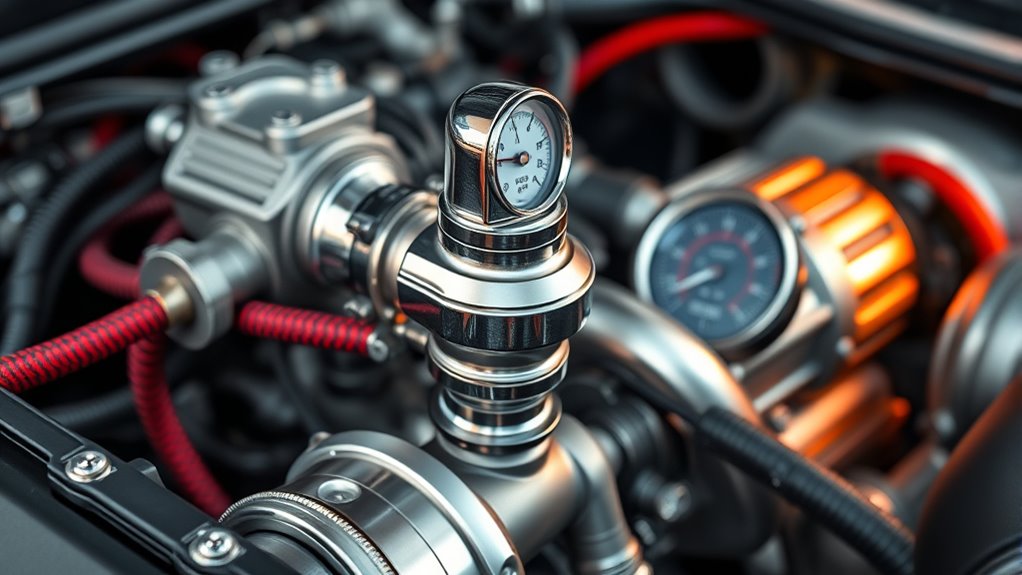

Proper setup and installation of boost control components are essential to guaranteeing your turbocharged system performs reliably and safely. Begin by evaluating your engine’s maximum safe boost limit and select compatible components, including boost controllers, wastegates, and BOVs. Understanding how these components operate together can help prevent damage and optimize performance. Confirm all parts fit properly with your vehicle’s existing hardware. Mount boost controllers in accessible locations for easy adjustments, and route wiring and hoses carefully to prevent interference or leaks. Connect solenoids correctly to the boost controller and engine management system. Install wastegates to regulate exhaust flow effectively, and position BOVs in the intake system to release excess pressure. After installation, thoroughly check for leaks and secure connections. Properly integrated components will help you monitor boost pressure accurately and maintain optimal engine performance while ensuring safety.

Tips for Optimizing Boost Control for Engine Safety and Performance

To optimize boost control for both safety and performance, it’s essential to fine-tune your system based on real-time engine conditions. Proper adjustments help prevent overboosting, reduce engine stress, and enhance responsiveness. Unleashing Power and Building Boost Since 1997, ensuring your boost system operates within safe parameters is crucial for long-term engine health. Focus on these key steps:

- Regularly monitor boost levels using gauges or controllers to ensure consistent operation.

- Adjust wastegate actuators for precise boost regulation, matching your driving conditions and engine specs.

- Seek professional tuning to calibrate fuel maps and boost settings, maximizing power while maintaining safety.

Frequently Asked Questions

How Does Ambient Temperature Influence Boost Pressure Accuracy?

Ambient temperature impacts boost pressure accuracy because warmer air is less dense, causing your turbocharger to work harder to maintain desired boost levels.

Higher temperatures can lead to less precise boost control, as sensors and wastegates mightn’t compensate adequately for the reduced air density. This can result in fluctuations or lower boost pressure, affecting engine performance.

To counteract this, tuning and cooling systems help maintain consistent boost regardless of temperature changes.

Can Boost Control Be Adjusted for Different Driving Conditions?

Yes, you can adjust boost control for different driving conditions. Electronic systems make it easy by allowing real-time, precise adjustments based on inputs like throttle position, RPM, and air temperature.

Manual controllers offer basic, user-made tweaks, while advanced strategies can automatically adapt boost levels to weather, load, or gear changes. This flexibility helps optimize performance, safety, and efficiency across various terrains and environments.

What Are Signs of a Failing Wastegate or Boost Controller?

Like a silent alarm, signs of a failing wastegate or boost controller alert you to trouble brewing. You might notice loss of power, erratic boost levels, or the check engine light flickering on.

Overboosting or boost creep can threaten your engine’s health. You’ll feel hesitation, increased fuel use, or misfires.

If these signs appear, it’s time to inspect your wastegate and boost control system before more serious damage occurs.

How Does Tuning Affect the Longevity of a Turbocharged Engine?

Tuning impacts your turbocharged engine’s longevity by optimizing fuel and timing maps to keep everything within safe limits. Proper tuning prevents excessive stress on components, reducing wear and tear.

It also guarantees boost pressure stays controlled, avoiding overheating and damage. When you tune carefully, you maintain engine reliability and extend its lifespan.

Conversely, aggressive or poorly executed tuning can cause premature engine failure, so always prioritize safe, precise adjustments.

Is External Wastegate Installation Suitable for All Vehicle Types?

You might wonder if external wastegate installation suits your vehicle. It’s ideal for high-performance, turbocharged engines needing precise boost control, especially in racing or modified setups.

However, they’re larger, more expensive, and require careful installation, including manifold design and placement at a 45° angle.

If your vehicle doesn’t demand high boost pressures or isn’t built for performance, internal wastegates could be a better, simpler choice.

Conclusion

Now that you’re a boost control expert, you can picture your turbocharged engine as a wild stallion, enthusiastic to run at full throttle. With proper setup, you’re the cowboy guiding that beast, ensuring it doesn’t run away or stumble over its own boost. Remember, a well-managed boost system isn’t just about power—it’s about keeping your engine’s wild spirit in check, so you can enjoy the ride without turning it into a fiery rodeo.